PCB Manufacturing Technical Requirements

-

PCB Size Specifications

– Ensure the circuit board dimensions meet specified size requirements with permissible deviations.

– Maintain board thickness within defined limits, including allowable variations.

– Critical perpendicularity of the board and edges must adhere to tolerance levels.

– Minimize warpage to ensure reliability during assembly and operation.

-

Appearance Criteria

– The PCB should be defect-free, avoiding cracks, scratches, burrs, and delamination.

– Quality standards for aluminum oxide film to prevent interference with electrical and mechanical properties.

-

Performance Specifications

– **Peel Strength**: Maintain adhesive bond strength for mechanical integrity.

– **Surface Resistivity**: Ensure surface resistivity does not impact signal integrity.

– **Minimum Breakdown Voltage**: PCB should withstand high voltages without breakdown.

– **Dielectric Constant**: Consistent signal transmission with minimal distortion.

– **Flammability**: Comply with fire safety standards.

– **Heat Resistance**: Maintain structural and electrical properties at high temperatures.

Measurement Methods for PCB Evaluation

-

Dielectric Constant and Dielectric Loss Factor

– Measure using a variable Q series resonance method for accurate data on electrical performance.

-

Thermal Resistance Measurement

– Calculate thermal resistance to understand heat dissipation capabilities.

Adhering to these technical requirements and measurement methods ensures the production of reliable PCBs for diverse electronic applications.

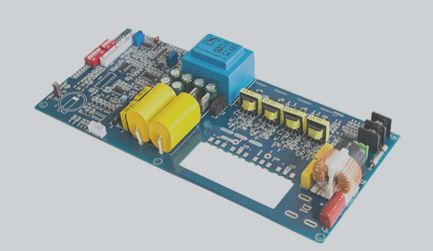

Aluminum PCB Manufacturing Process Insights

1. Machining and Punching Challenges

Aluminum PCBs, known for durability and thermal management, pose challenges during manufacturing, especially in drilling and punching processes.

-

Drilling and Burrs

– Precision drilling is crucial to avoid burrs that can impact board quality and soldering.

-

Punching and Molding

– Advanced molds are essential for accurate shapes and clean edges post-punching.

– Use military-grade models to ensure precise hole placement and minimal stress on the board.

2. Surface Protection and Handling

Protect aluminum substrates from environmental factors and improper handling to maintain board functionality.

Avoiding Surface Damage

- Contact with the aluminum base surface must be avoided during production to prevent discoloration or oxidation.

- Passivation technology or protective films are used to maintain surface integrity.

High Voltage Testing

- Communication power supply aluminum PCBs undergo rigorous high-voltage tests for safety.

- Overvoltage tests are conducted at voltages between 1500V and 1600V for 5 to 10 seconds.

- Contamination or insulation on the surface can lead to electrical failures.

Aluminum PCB Manufacturing Specifications

- Thicker copper foil, typically 3 ounces or more, is used for high-power applications.

- Protective films are crucial to prevent chemical corrosion during processing.

Milling and Cutting Considerations

- Milling aluminum substrates requires harder and slower cutters compared to fiberglass boards.

- Proper heat management is essential during the milling process to prevent deformation.

In conclusion, manufacturing aluminum PCBs demands precision, quality control, and careful handling to ensure top performance. By following best practices such as surface protection, thorough testing, and precise milling, manufacturers can deliver high-quality aluminum PCBs for demanding applications.