Handling 100A Current on PCBs: Methods and Solutions

Introduction

When it comes to PCB design, the typical current capacity is usually below 10A, but in certain cases, it can reach up to 80A or even higher. To handle currents exceeding 100A, special considerations and methods need to be implemented.

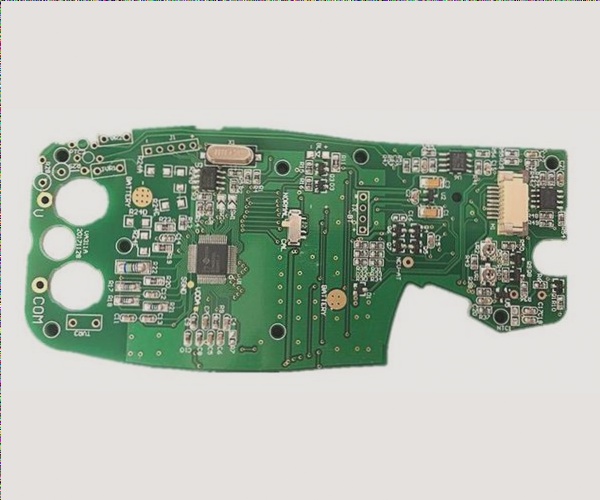

Method 1: PCB Layout Design

- Understanding Resistance: The resistance of a PCB trace depends on its material, cross-sectional area, and length. To carry high currents, traces should be short and thick, with thicker copper being more effective.

- Key Parameters for Evaluation: In practical PCB design, factors like copper thickness, temperature rise, and trace width are crucial for determining the current-carrying capacity.

- Enhancing Capacity: Increasing copper thickness, widening trace width, and improving heat dissipation can all enhance the PCB’s ability to handle high currents.

Method 2: Terminal Connections

Terminal blocks can be used in conjunction with PCB traces to handle high currents. By connecting wires to terminals capable of handling 100A, safety and reliability can be maintained.

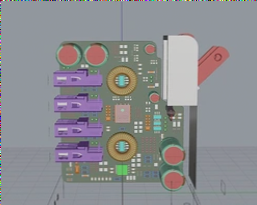

Method 3: Customized Copper Busbars

Custom copper busbars offer a solution for carrying large currents on PCBs. These busbars are designed to handle higher current loads than traditional PCB traces.

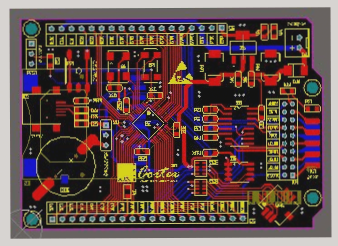

Method 4: Special PCB Manufacturing Processes

Specialized PCB manufacturing techniques, such as 3-layer copper designs, can be employed to create PCBs specifically tailored for high-current applications. These PCBs can efficiently handle currents of 100A or more within a compact form factor.

If you require PCB manufacturing services tailored to handle high currents, feel free to contact us.