PCB Design Best Practices for Layout and Routing

When designing a PCB, it is crucial to consider various factors at different stages, including grid points used during layout. Here are some key points to keep in mind:

Grid Point Considerations:

- For large components like ICs and connectors, a grid accuracy of 50 to 100 mils is sufficient.

- Smaller passive components such as resistors and capacitors benefit from a finer grid of 25 mils.

- Using appropriate grid points aids in component alignment and enhances layout aesthetics.

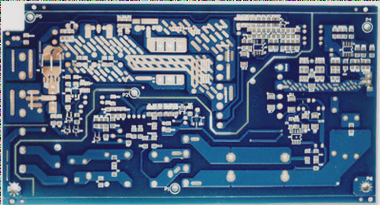

Routing PCB Traces:

When routing PCB traces, consider the following guidelines:

- Components should ideally be placed on the same side of the board.

- Components must be arranged neatly on a grid, avoiding overlap.

- Maintain a minimum distance of 1mm between adjacent pads of different components.

- Keep a distance of at least 2mm from the edge of the PCB.

- Consider a rectangular PCB shape with an aspect ratio of 3:2 or 4:3 for mechanical strength.

Layout Techniques:

Follow these techniques for an efficient PCB layout:

- Analyze functional units to determine component placement based on signal flow.

- Position core components centrally and arrange surrounding components uniformly.

- For high-frequency circuits, carefully arrange components in parallel for optimal performance.

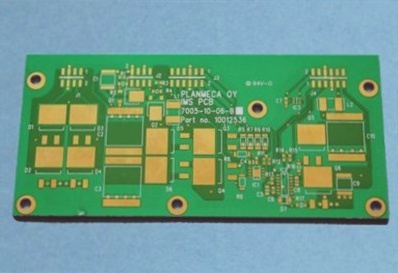

Special Components and Layout Design:

Special components in PCB design require careful placement:

- Consider special components’ impact on circuit compatibility, signal integrity, and heat generation.

- Balance PCB size to avoid impedance issues and interference between traces.

- Position special components first and then layout remaining components accordingly.