Effective Heat Dissipation Techniques for PCB Circuit Boards

Electronic devices generate heat during operation, which can lead to overheating and decreased performance if not properly managed. Implementing effective heat dissipation treatments for PCB boards is crucial to ensure optimal performance. Let’s explore some key heat dissipation techniques for PCB circuit boards:

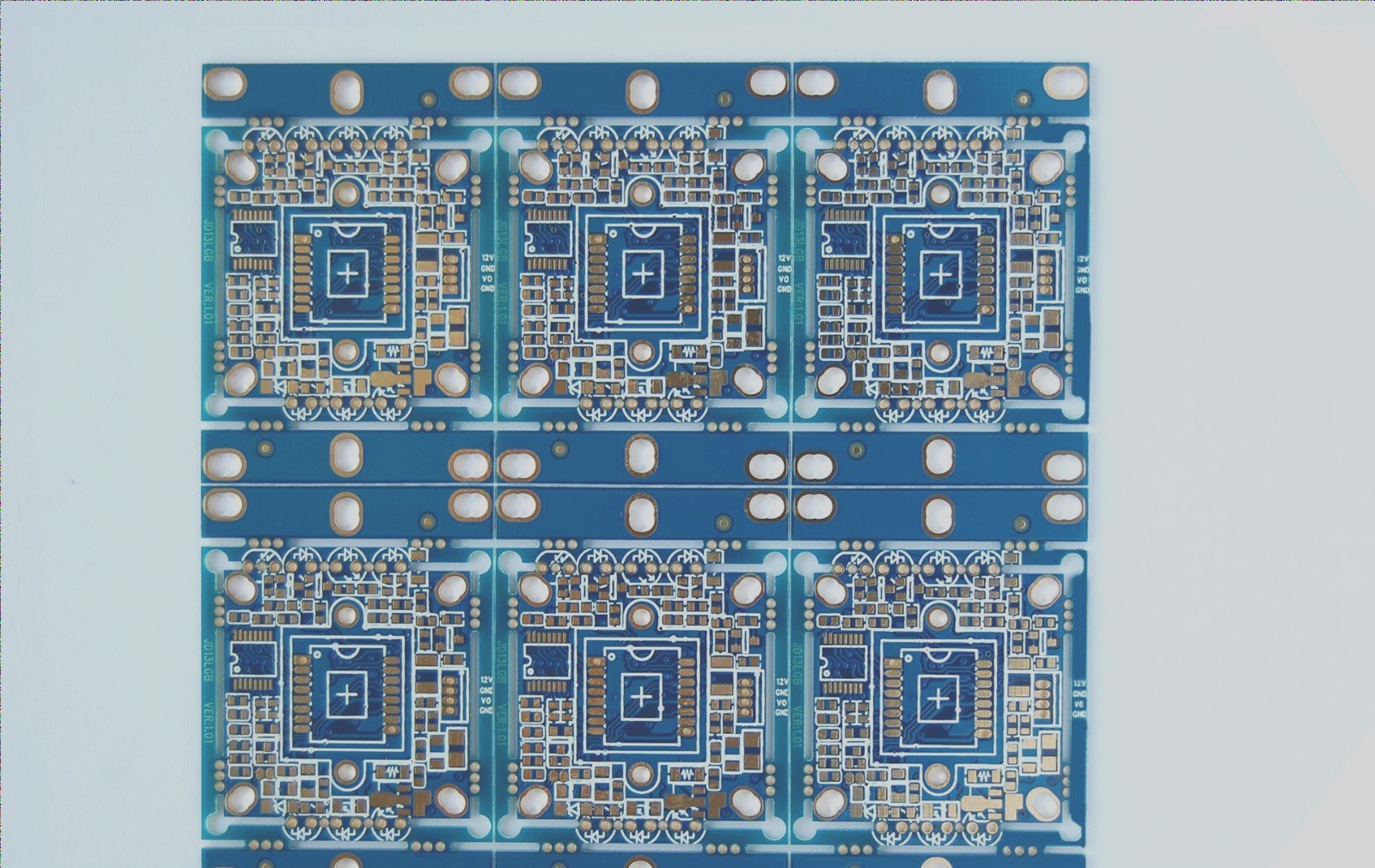

1. Heat Dissipation Through the PCB Itself

- Enhance the heat dissipation capacity of the PCB itself, especially in areas in direct contact with heating elements.

- Add heat-dissipating copper foil and utilize thermal vias to improve heat dissipation.

- Expose copper on the back of ICs to reduce thermal resistance.

2. Placement Strategies

- Position thermally sensitive devices in areas with cold airflow.

- Place temperature detection devices in the hottest spots.

- Arrange devices based on their heat generation and dissipation capabilities.

- Optimize airflow paths and component configuration to reduce resistance.

3. Adding Radiators and Heat-conducting Plates

For PCBs with high-heat-generating devices, consider adding radiators or heat-conducting plates to enhance cooling efficiency.

4. Design Considerations

- Maximize copper foil utilization in routing designs for improved heat dissipation.

- Analyze thermal efficiency and avoid hotspots that could impact circuit operation.

By incorporating these heat dissipation strategies into PCB design, you can improve the reliability and performance of electronic devices by effectively managing internal temperatures.