Mainstream PCB Testing Methods

-

Manual Visual Inspection

Manual visual inspection involves visually checking component placement on the PCB for defects. While cost-effective, it may not be suitable for high-volume production due to limitations in defect detection.

-

Automated Optical Inspection (AOI)

AOI is an efficient method for identifying manufacturing defects before and after soldering. It excels in checking component polarity and presence but has limitations in short-circuit detection.

-

Functional Testing

Functional testing evaluates the PCB’s performance under real-world conditions to ensure proper functionality. It is effective in detecting defects that visual inspection may miss.

-

In-Circuit Testing (ICT)

ICT is an electrical test method that checks for defects by applying signals to components. It provides detailed feedback on the PCB’s electrical integrity but may not be suitable for all designs.

-

X-ray Inspection

X-ray inspection is a non-destructive method used to detect hidden defects in PCBs, such as voids in solder joints. It is ideal for complex designs but requires specialized equipment.

Functional Testing is a fundamental automatic testing method that ensures the reliability of PCBs. It includes Final Product Testing (FPT) and the latest Hot Mock-up model testing.

The Importance of PCB Testing Methods in Electronics Manufacturing

The Flying Probe Tester, also known as the Probe Tester, has become a popular testing method in recent years due to its improved mechanical accuracy, speed, and reliability. This testing method is particularly favored for its ability to quickly adapt to different testing requirements without the need for fixtures, making it ideal for prototype and low-volume production.

Advantages of the Flying Probe Tester

- Fast Time To Market (TTM)

- Automatic test generation

- No fixture costs

- Strong diagnostic capabilities

- Easy programming

PCB Manufacturing Defect Analyzer (MDA)

The MDA is a valuable tool for identifying manufacturing defects in high-volume, low-mix environments. While it offers benefits such as low initial cost, high throughput, and comprehensive testing for short and open circuits, there are limitations to consider. Functional testing is not possible, there is no test coverage indication, fixtures are necessary, and overall testing costs may be higher.

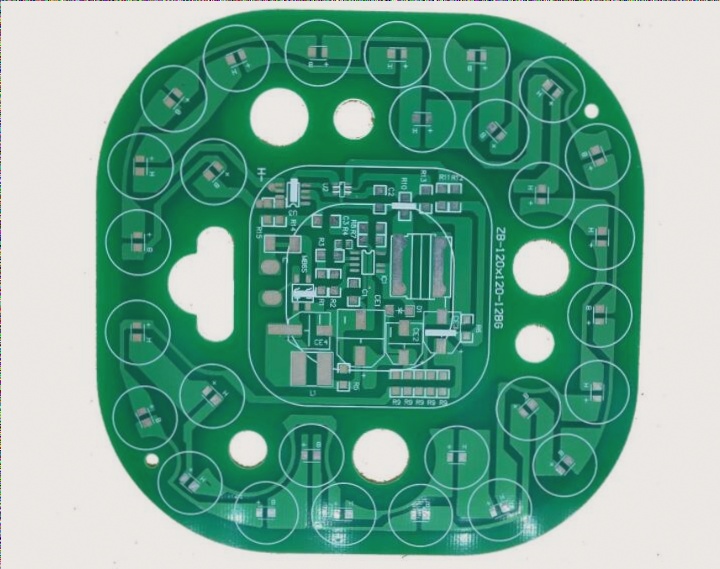

Importance of PCB Testing

PCBA circuit boards contain numerous circuits and components, making thorough testing essential to ensure product quality and delivery reliability. It is crucial to understand and utilize the various PCB testing methods available to achieve optimal results.

For Your PCB Manufacturing Needs

If you require PCB manufacturing services, feel free to contact us for assistance.