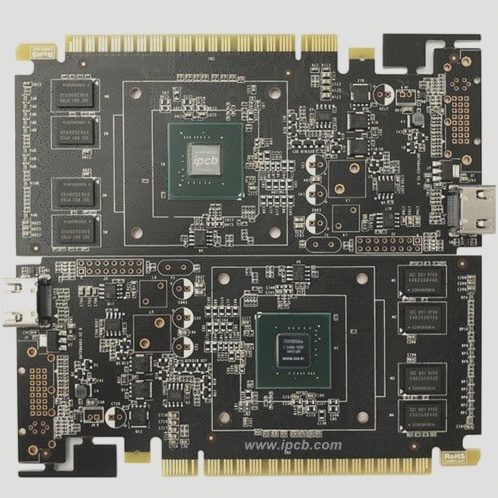

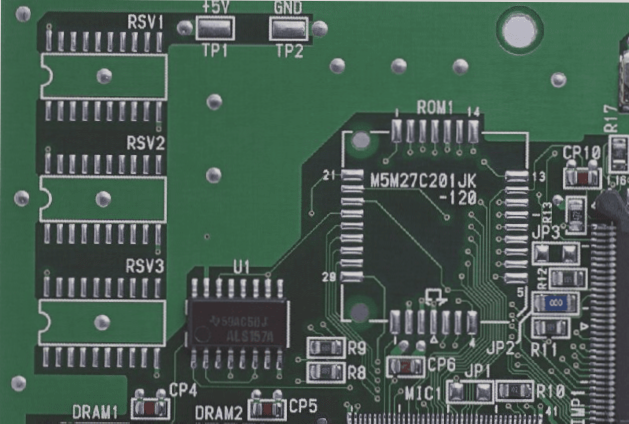

At first glance, regardless of the internal quality of the PCB board, the surface often appears similar. However, it is through the surface that we can discern crucial differences, which are vital to the PCB’s durability and functionality throughout its life.

Whether in the manufacturing assembly process or during actual use, a PCB must exhibit reliable performance, which is crucial. In addition to associated costs, defects in the assembly process can be carried into the final product by the PCB, potentially leading to malfunctions and claims. Therefore, from this perspective, it is not an exaggeration to say that the cost of a high-quality PCB is minimal. In all market segments, especially those involving key application areas, the consequences of such failures can be disastrous.

When comparing PCB prices, these factors should be considered. Although the initial cost of reliable, guaranteed, and long-lasting products may be high, they offer significant value in the long run. Let’s delve into the 14 most important characteristics of high-reliability circuit boards:

1. 25-micron hole wall copper thickness

Benefit:

Enhances reliability, including improved resistance to z-axis expansion.

Risks of not doing this:

Potential for blow holes or degassing, electrical connectivity issues during assembly (inner layer separation, hole wall breakage), or failure under load conditions in actual use. IPC Class 2 (the standard adopted by most factories) requires 20% less copper plating.

2. No welding repair or open circuit repair

Benefit:

Ensures a perfect circuit for reliability and safety, no maintenance, no risk.

Risks of not doing this:

Improper repairs can lead to circuit board damage. Even if repaired ‘properly’, there is a risk of failure under load conditions (vibration, etc.), which may cause failures in actual use.

3. Exceeding the cleanliness requirements of IPC specifications

Benefit:

Enhancing PCB cleanliness can improve reliability.

Risks of not doing this:

1. Residues and solder accumulation on the circuit board pose risks to the solder mask. Ionic residues can lead to corrosion and contamination on the soldering surface, which may cause reliability issues such as poor solder joints and electrical failures, ultimately increasing the probability of actual failures.

2. Strictly controlling the service life of each surface treatment

Benefit: Ensures solderability, reliability, and reduces the risk of moisture intrusion.

Risk of not doing so: Metallographic changes in the surface treatment of older circuit boards can lead to soldering problems. Moisture intrusion may cause delamination, separation (open circuits), or issues with the inner layer and hole wall during assembly and/or actual use.

3. Use internationally renowned substrates—avoid “local” or unknown brands.

Benefit: Enhances reliability and ensures known performance.

Risk of not doing so: Poor mechanical performance may prevent the circuit board from performing as expected under assembly conditions. High expansion performance can lead to delamination, disconnection, and warpage problems. Weakened electrical characteristics can result in poor impedance performance.

4. Ensure the tolerance of the copper clad laminate meets IPC-4101 Class B/L requirements.

Benefit: Strictly controlling the dielectric layer thickness reduces deviations in expected electrical performance.

Risk of not doing so: Electrical performance may fail to meet specified requirements, resulting in significant variability in output and performance across components from the same batch.

5. Define solder mask materials to ensure compliance with IPC-SM-840 Class T requirements.

Benefit: NCAB Group recognizes “excellent” inks, ensures ink safety, and guarantees that solder mask inks meet UL standards.

Risk of not doing so: Inferior inks can cause issues with adhesion, flux resistance, and hardness, leading to the solder mask separating from the circuit board and eventually causing copper circuit corrosion. Poor insulation properties can result in short circuits due to accidental electrical continuity or arcing.

6. Define tolerances for shapes, holes, and other mechanical features.

Benefit: Strict tolerance control improves dimensional quality, fit, shape, and function of products.

Risk of not doing so: Assembly issues may arise, such as alignment or fitting problems, which may only become apparent during assembly. Increased size deviations can also cause difficulties when installing into the base.

7. NCAB specifies the thickness of the solder mask, even though IPC does not have relevant regulations.

Benefit: Improves electrical insulation properties, reduces the risk of peeling or loss of adhesion, and strengthens resistance to mechanical impact, regardless of the impact location.

Risk of not doing so: A thin PCB solder mask can lead to adhesion, flux resistance, and hardness issues, causing the solder mask to separate from the circuit board and eventually resulting in copper circuit corrosion. Poor insulation from a thin solder mask can also cause short circuits due to accidental conduction or arcing.

8. Define appearance and repair requirements, even though IPC does not specify them.

Benefit: Ensures careful handling and attention to safety during the PCB manufacturing process.

Risk of not doing so: Scratches, minor injuries, and repairs may affect the circuit board’s appearance. Besides visible surface issues, there could be hidden risks impacting assembly and actual use.

Whether in the manufacturing assembly process or during actual use, a PCB must exhibit reliable performance, which is crucial. In addition to associated costs, defects in the assembly process can be carried into the final product by the PCB, potentially leading to malfunctions and claims. Therefore, from this perspective, it is not an exaggeration to say that the cost of a high-quality PCB is minimal. In all market segments, especially those involving key application areas, the consequences of such failures can be disastrous.

When comparing PCB prices, these factors should be considered. Although the initial cost of reliable, guaranteed, and long-lasting products may be high, they offer significant value in the long run. Let’s delve into the 14 most important characteristics of high-reliability circuit boards:

1. 25-micron hole wall copper thickness

Benefit:

Enhances reliability, including improved resistance to z-axis expansion.

Risks of not doing this:

Potential for blow holes or degassing, electrical connectivity issues during assembly (inner layer separation, hole wall breakage), or failure under load conditions in actual use. IPC Class 2 (the standard adopted by most factories) requires 20% less copper plating.

2. No welding repair or open circuit repair

Benefit:

Ensures a perfect circuit for reliability and safety, no maintenance, no risk.

Risks of not doing this:

Improper repairs can lead to circuit board damage. Even if repaired ‘properly’, there is a risk of failure under load conditions (vibration, etc.), which may cause failures in actual use.

3. Exceeding the cleanliness requirements of IPC specifications

Benefit:

Enhancing PCB cleanliness can improve reliability.

Risks of not doing this:

1. Residues and solder accumulation on the circuit board pose risks to the solder mask. Ionic residues can lead to corrosion and contamination on the soldering surface, which may cause reliability issues such as poor solder joints and electrical failures, ultimately increasing the probability of actual failures.

2. Strictly controlling the service life of each surface treatment

Benefit: Ensures solderability, reliability, and reduces the risk of moisture intrusion.

Risk of not doing so: Metallographic changes in the surface treatment of older circuit boards can lead to soldering problems. Moisture intrusion may cause delamination, separation (open circuits), or issues with the inner layer and hole wall during assembly and/or actual use.

3. Use internationally renowned substrates—avoid “local” or unknown brands.

Benefit: Enhances reliability and ensures known performance.

Risk of not doing so: Poor mechanical performance may prevent the circuit board from performing as expected under assembly conditions. High expansion performance can lead to delamination, disconnection, and warpage problems. Weakened electrical characteristics can result in poor impedance performance.

4. Ensure the tolerance of the copper clad laminate meets IPC-4101 Class B/L requirements.

Benefit: Strictly controlling the dielectric layer thickness reduces deviations in expected electrical performance.

Risk of not doing so: Electrical performance may fail to meet specified requirements, resulting in significant variability in output and performance across components from the same batch.

5. Define solder mask materials to ensure compliance with IPC-SM-840 Class T requirements.

Benefit: NCAB Group recognizes “excellent” inks, ensures ink safety, and guarantees that solder mask inks meet UL standards.

Risk of not doing so: Inferior inks can cause issues with adhesion, flux resistance, and hardness, leading to the solder mask separating from the circuit board and eventually causing copper circuit corrosion. Poor insulation properties can result in short circuits due to accidental electrical continuity or arcing.

6. Define tolerances for shapes, holes, and other mechanical features.

Benefit: Strict tolerance control improves dimensional quality, fit, shape, and function of products.

Risk of not doing so: Assembly issues may arise, such as alignment or fitting problems, which may only become apparent during assembly. Increased size deviations can also cause difficulties when installing into the base.

7. NCAB specifies the thickness of the solder mask, even though IPC does not have relevant regulations.

Benefit: Improves electrical insulation properties, reduces the risk of peeling or loss of adhesion, and strengthens resistance to mechanical impact, regardless of the impact location.

Risk of not doing so: A thin PCB solder mask can lead to adhesion, flux resistance, and hardness issues, causing the solder mask to separate from the circuit board and eventually resulting in copper circuit corrosion. Poor insulation from a thin solder mask can also cause short circuits due to accidental conduction or arcing.

8. Define appearance and repair requirements, even though IPC does not specify them.

Benefit: Ensures careful handling and attention to safety during the PCB manufacturing process.

Risk of not doing so: Scratches, minor injuries, and repairs may affect the circuit board’s appearance. Besides visible surface issues, there could be hidden risks impacting assembly and actual use.