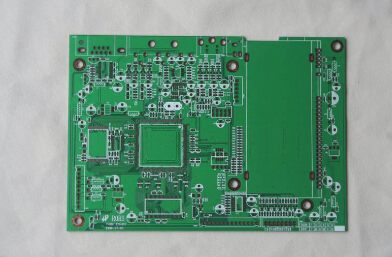

1. Producing PCB boards according to specific techniques is not a straightforward task.

2. PCB manufacturing is not inherently difficult; the real challenge lies in troubleshooting after production is complete.

3. Both hobbyists and industry engineers face issues while debugging PCB circuit boards, much like programmers encounter bugs.

4. Some individuals have a keen interest in debugging PCB circuit boards, akin to programmers fixing errors.

5. Common challenges include circuit board design flaws, damage to electronic components, short circuits, and disconnections in PCB circuit boards.

6. Damaged diode ring color resistance can be particularly problematic.

7. Typical PCB circuit board failures primarily occur in integrated chips and components like capacitors, resistors, inductors, diodes, and crystal oscillators.

8. An intuitive approach to identifying component failures often involves visual inspection, where burn marks on electronic components are evident.

9. In such cases, the faulty component can usually be replaced directly.

—

Let me know if you need anything else!

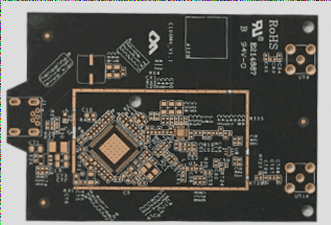

1. **Suspected damaged parts.** In reality, this component is not damaged.

2. Not all electronic components are visible to the naked eye, such as resistors, capacitors, and diodes. Sometimes, damage isn’t apparent from the surface. Professional inspection tools, like multimeters and capacitance meters, are essential for checking the voltage or current ranges of electronic components. Results may indicate the need for direct replacement or further inspection of the component or its predecessors.

3. The PCB may appear intact, yet the fault remains undetectable.

4. If a component is truly broken, both visual inspection and instruments can identify it. However, there are instances when a component on the PCB seems fine, yet the circuit board fails to function properly. Many beginners resort to creating a new board or purchasing one. Often, the interaction among components can lead to instability during installation.

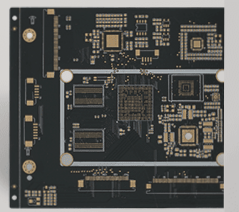

5. The circuit blocks of the circuit board can be segmented.

6. In such cases, instruments become less useful, necessitating a focused approach to isolate the fault based on current and voltage readings. Experienced engineers can swiftly identify fault zones but cannot guarantee that a specific component is defective. The only reliable method is to replace suspected components until the faulty one is identified. For instance, while repairing a laptop motherboard, no faults were found initially, but three parts were replaced: the power supply chip, a diode, and a USB charging element (the blue socket for charging when powered off). Eventually, through wave detection, it was discovered that the issue was a short circuit in the components near the South Bridge chip.

7. The circuit board is critical.

8. Given that the PCB serves as the foundation for the components, failures are inevitable. A common issue occurs when tin connections break during PCB corrosion, often due to the manufacturing process. In such cases, if wires cannot be supplemented, using thin copper wires is the only solution.

9. **PS:** PCB circuit board failures can be quite frustrating; often, there is no visible damage, leading to focus during the troubleshooting process. When an issue is resolved, it brings an inexplicable sense of accomplishment—similar to how programmers debug errors.