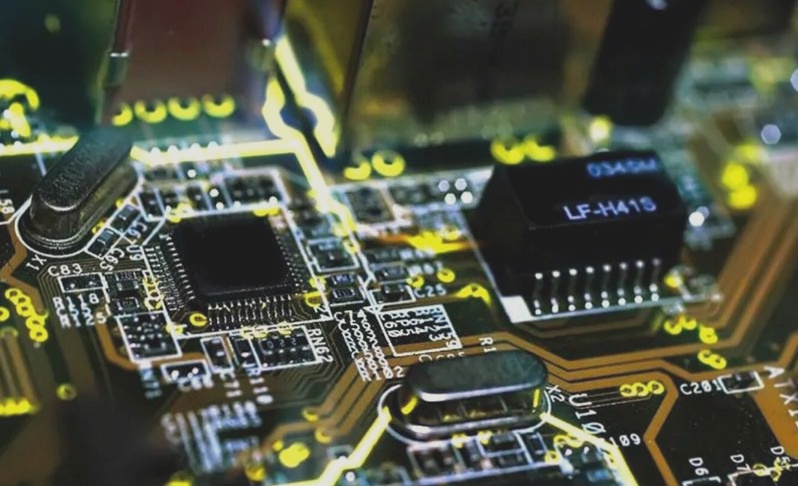

Optimizing PCB Layouts: The Significance of Copper Placement

- Common Practice:

- After completing the wiring, spare PCB space is often designated as the datum surface for copper placement, a practice well-known to PCB engineers.

- Unveiling the Advantages:

- Addressing the question of why copper is laid in PCBs, the focus is on improving system performance and mitigating interference.

- Ground Impedance Reduction:

- Emphasizes the importance of reducing ground impedance for digital circuits, enhancing anti-interference capabilities through extensive copper laying or complete ground planes.

- Power Supply Efficiency:

- Discusses how copper laying minimizes DC resistance on power transmission paths, leading to reduced voltage drops and improved power supply transmission efficiency.

- Optimizing Backflow Paths:

- Highlights the connection between ground wires and copper laying, maximizing power supply backflow paths, minimizing power loop areas, and boosting system anti-interference abilities.

- Signal Protection and Isolation:

- Illustrates the use of copper to protect and isolate important and high-speed signals, contributing to overall system reliability.

- Heat Dissipation Enhancement:

- Explores the capability of copper skin to transmit heat, enhancing system heat dissipation through extensive copper laying and grounding.

- Multilayer Considerations:

- Considers the necessity of multiple ground planes in a multilayer board to address impedance, resistance, loop, and heat dissipation challenges.

- Electrical Performance vs. Process Considerations:

- Balances electrical performance considerations with the practicalities of electroplating and lamination, emphasizing the importance of copper laying in blank spaces for optimal processing.

- Achieving Theoretical Precision:

- Discusses the need for a close-to-100% copper residue rate in inner layers to align theoretical calculations with the actual finished product, ensuring optimal lamination and impedance considerations.

In summary, copper placement in PCB layouts significantly contributes to electrical performance, interference reduction, power supply efficiency, and heat dissipation, making it a critical aspect of effective PCB design and manufacturing.