Lead-free Surface Finish Techniques Overview

The transition to lead-free surface finish techniques hinges on scientific research, promotion, and influence. While OSP technology offers a flat surface without the need for extended shelf life or multiple heating applications, challenges like high-temperature processing may impede the widespread adoption of lead-free HASL. Recent enhancements in heat resistance and cost-effectiveness position OSP as a viable alternative to HASL in various applications.

ENIG technology, known for providing superior protection in contact and bonding scenarios, faces competition from emerging I-Ag technology due to cost considerations. The cost advantage of I-Ag in bonding applications may surpass ENIG, especially for high-quality products seeking efficient solutions in certain cases.

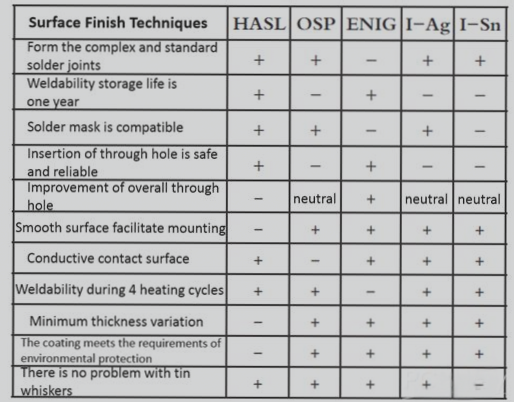

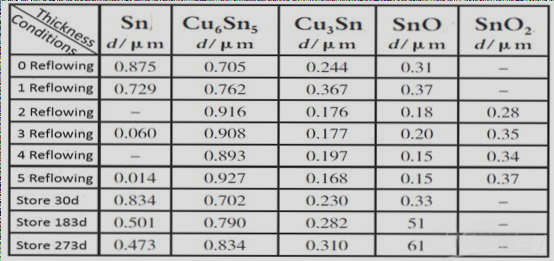

Explore the performance comparison of different surface treatment processes in the table below.

Reflow Times Impact on PCB Surface Finish

ENIG maintains solderability through repeated reflow cycles, unlike HASL, OSP, and Ag, which experience a decline in solderability with each reflow. The OSP interface particle diameter increases by 30% compared to the I-Ag interface after four reflows due to thin sheet block formation hindering Cu and Sn mutual diffusion, leading to interface layer thinning. Sn solderability diminishes rapidly due to Sn-Cu compound formation and oxide creation.

Nitrogen Protection Influence on PCB Surface Finish

Nitrogen protection enhances wetting and spreading when combined with Sn-Pb solder and a PCB surface protection layer. However, the benefits of nitrogen protection are not as pronounced with lead-free solders. ENIG, OSP, and I-Ag solderability improves in a nitrogen atmosphere, with minimal variation in OSP and I-Ag based on testing methods. ENIG shows enhanced weldability in a nitrogen environment, highlighting the impact of solder activity on wettability.

Nitrogen Protection Effect

When it comes to protection during wave soldering, the superiority of nitrogen over high-activity solder is evident. The spreadability of solder alloy on various coating surfaces after different reflow times in an air environment is depicted in the table below.

Surface Finish Comparison

The table below showcases the wettability of solder alloys on different coating surfaces after varying reflow times in an air environment.

Solder Spreadability

The behavior of surface coating spreadability is primarily influenced by the coating itself when reflow cycles are minimal. However, with an increase in reflow cycles, the protective coating begins to exhibit an impact. Notably, surface finish failures with Sn-based coatings occur more rapidly.

Conclusion:

I-Sn coatings show a rapid degradation in solderability, increasing the likelihood of the “whisker” phenomenon. Lead-free solder, compared to I-Sn coatings, displays minimal spread rate differences, while lead-based solder presents a significantly higher spread rate. HASL coatings encounter challenges with poor surface smoothness and the “whisker” issue. SAC and Sn-Ag alloys, commonly selected for lead-free surface finishes, offer good tolerance and low defect rates, making them ideal for non-fine-pitch assemblies. ENIG coatings are preferred in fine-pitch bonding and high-reliability applications due to their excellent weldability, low reliance on interfacial compounds, and smooth surface. However, ENIG coatings are pricier and involve a complex process, potentially leading to “black pad” formation. I-Ag coatings have emerged as a popular alternative. OSP coatings, despite their affordability and short-term storage capabilities, are primarily utilized in simpler products.

For inquiries related to PCBs and PCBA, feel free to reach out to me at info@wellcircuits.com.