Statistical Process Control (SPC) in PCBA Production

Statistical Process Control (SPC) is a method that utilizes statistical analysis techniques to monitor the production process in real-time. It helps distinguish between random fluctuations and abnormal variations in product quality during manufacturing, enabling production managers to address issues promptly and enhance quality control.

Fluctuations in PCBA Production

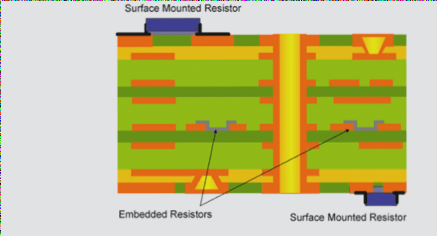

Fluctuations in product dimensions are inevitable in PCBA production and can stem from various factors like personnel, machinery, materials, methods, and the environment. These fluctuations can be categorized as normal or abnormal. Normal fluctuations are caused by accidental factors and have minimal impact on product quality, while abnormal fluctuations result from systemic issues and significantly affect product quality.

Role of SPC in PCBA Production

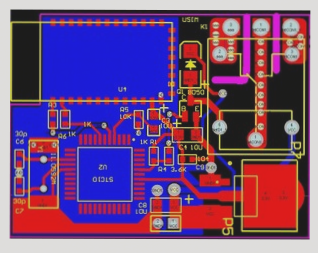

- Product Categories and Information: Each PCBA processing company has unique characteristics, requiring flexibility in planning product categories and materials.

- Inspection and Inspection Stations: The inspection department evaluates product quality, but identifying underlying issues and quality improvements falls under technical and production departments.

- Defect Categories and Codes: Standardized defect categories help in identifying and resolving issues like misalignment, solder paste bridging, and component displacement during the production process.