Introduction:

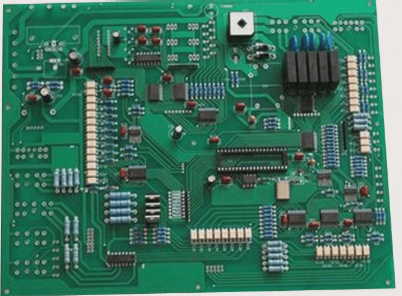

The assembly process for flexible PCBs resembles that of rigid PCBs but may involve different procedures based on specific needs. A typical single-sided flexible PCB assembly process is depicted in Figure 1.

Characteristics of Flexible PCB Assembly:

Flexible PCB Mounted on Rigid PCB:

Due to their lightweight and thin structure, flexible PCBs can deform and cannot be directly assembled on SMT production lines like rigid PCBs. Hence, they need to be mounted on a rigid PCB substrate to simulate rigid PCB properties during assembly. The substrate’s flatness, positioning accuracy, and consistency are vital for ensuring high product quality and successful assembly.

Low Component Density:

Flexible PCBs are currently pricier than rigid PCBs and are typically used to connect various functional modules. They usually have a low component count, usually under 50 components or just two connectors.

Panelization:

Flexible PCBs are commonly found in compact electronic devices like mobile phones and digital cameras. Their small single-sided flexible PCB area and limited component count lead to the use of panels for multiple flexible PCBs in factories. These panels are later separated through V-cutting or V-scoring post-assembly to enhance efficiency.

High Product Quality Requirements:

Flexible PCBs are utilized in environments requiring frequent bending and precise control. Components on these PCBs must meet specific operational standards, leading to stringent quality control requirements for assembly, including cleanliness, anti-static measures, and soldering reliability. The adoption of lead-free technology has introduced additional challenges in flexible PCB assembly.

Higher Assembly Costs:

The Advantages of Flexible PCB Assembly

Flexible PCB assembly differs significantly from rigid PCB assembly due to the need for specialized fixtures, longer production cycles, lower equipment utilization rates, and increased components and operators. These unique characteristics, coupled with strict production environment and quality control standards, result in higher overall assembly costs, especially during the initial investment phase.

Recent Developments in Flexible PCB Technology

With the continuous evolution of electronic products, the utilization of flexible PCBs is on the rise, and advancements in their assembly processes are ongoing. These advancements are driving a reduction in manufacturing and assembly expenses, thereby broadening the scope of flexible PCB applications and creating a positive cycle of increased adoption.

Future Outlook for Flexible PCBs

The future of flexible PCBs looks promising as technology continues to improve and costs decrease. The versatility and efficiency of flexible PCB assembly are set to revolutionize the electronics industry, making these boards an integral part of next-generation electronic devices.

- Enhanced flexibility and durability

- Improved performance in compact designs

- Cost-effective solutions for complex electronic systems

If you require further information on PCBs or PCBA, please do not hesitate to reach out to us at info@wellcircuits.com.