The Latest Trends in FPC Manufacturing

Introduction to FPC

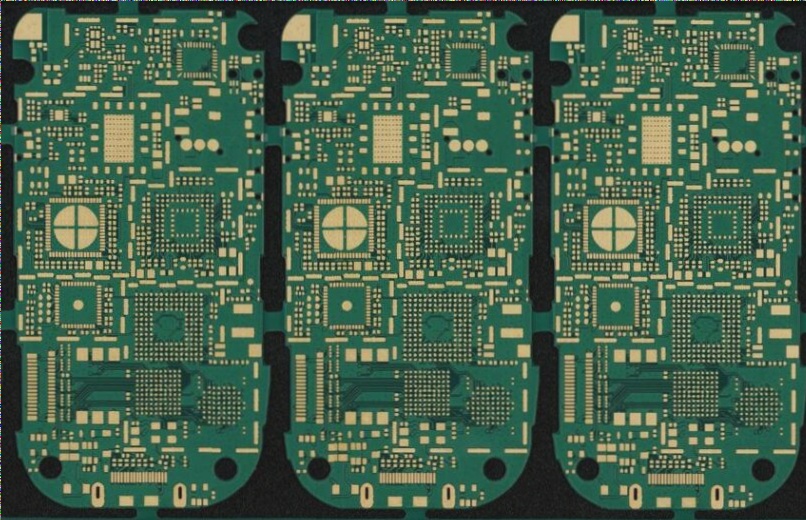

FPC (Flexible Printed Circuit) are flexible circuit boards that offer high wiring density, lightweight construction, and thin profiles. They are widely used in devices like mobile phones, laptops, and digital cameras.

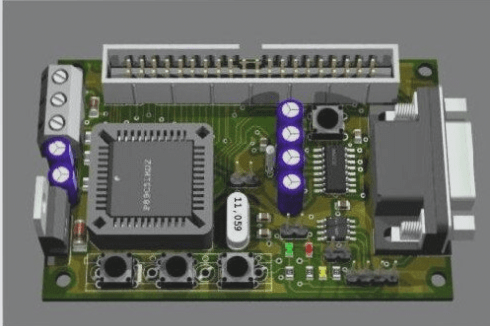

Current Advancements in PCB Technology

In recent years, PCB manufacturing technology has rapidly advanced, leading to increased demands for FPC. Precision PITCH is seen as a key area for future breakthroughs in FPC development.

Effective Control in FPC Manufacturing

- Design: Consider the expansion rate of crimping fingers in initial circuit design for effective control. Distribute design elements evenly and symmetrically across the layout.

- Material Selection: Ensure the adhesive thickness for the cover film matches the copper foil’s thickness to prevent product deformation.

- Process Design: Cover all copper foil sections with the cover film and avoid uneven pressure during pressing to maintain stability.

Key Points in Manufacturing

- Material Storage: Strictly follow supplier-specified conditions for proper material storage.

- Drilling: Bake the substrate before drilling to minimize expansion and shrinkage due to high moisture content.

- Electroplating: Use short-side splints to reduce deformation caused by water stress during swing.

- Pressing: Control glue application and ensure stable temperature and humidity throughout the production process.

- Baking: Proper baking is essential for fast-pressed products to avoid ongoing production or usage issues.

Quality Assurance in FPC Manufacturing

Consistent quality in FPC manufacturing requires adherence to specific requirements from material storage to packaging and customer guidance. Ensure customers face no issues during product usage by providing proper storage instructions.

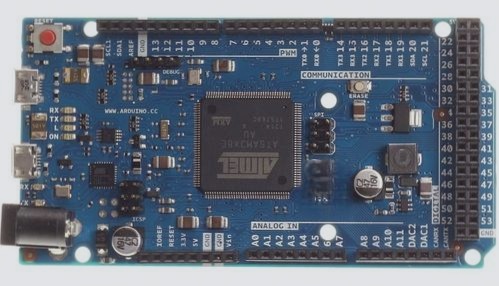

Concluding Thoughts on Future Trends in PCB Industry:

In the near future, the PCB industry is expected to witness a surge in demand for smaller, more intricate, and higher-priced flex circuits. This trend will require the development of innovative assembly techniques and the incorporation of hybrid flex circuits. To stay abreast of the rapid advancements in computing, telecommunications, consumer preferences, and dynamic markets, the flexible circuit sector must capitalize on its technological expertise. Our PCB manufacturing and processing division boasts a team of highly trained technicians and frontline operators who form a solid foundation, ensuring that product quality surpasses 99% compliance with IPC-A-610C CLASS 2 and our internal standards.