The advantages of SMT chip processing packaging over traditional packaging

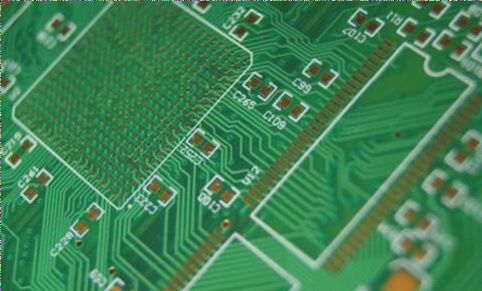

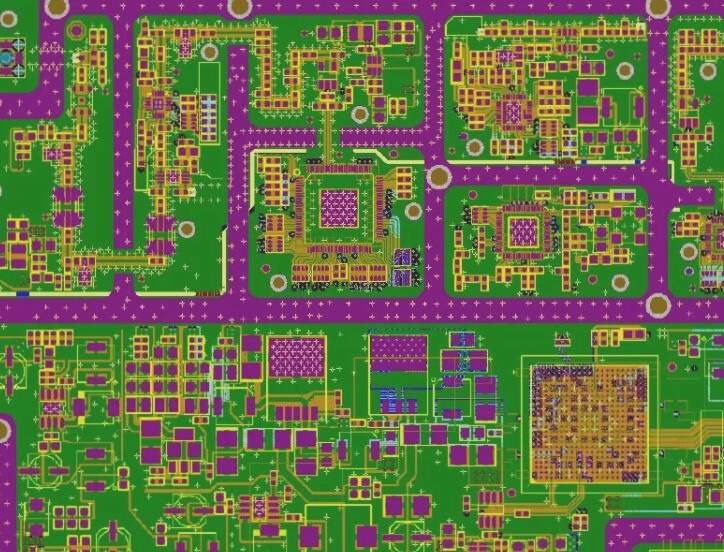

1. **Smaller Size and Higher Installation Density**

SMT chip electronic components are approximately 10% the size of traditional components and weigh about 10% as much. SMT technology can reduce electronic equipment size by 40% to 60% and its mass by 60% to 80%, significantly decreasing both area and weight. The grid for SMT components has evolved from 1.27mm to 0.63mm, with some reaching 0.5mm. Through-hole installation technology can further enhance relative density.

2. **High Reliability and Enhanced Anti-Vibration Ability**

SMT chip components offer high reliability, compact size, lightweight, and strong anti-vibration capabilities. Automated production leads to high installation reliability, with defect rates in solder joints usually below 10 parts per million. In contrast, the defect rate in wave soldering for through-hole components is significantly higher, leading to lower overall reliability. As a result, nearly 90% of electronic equipment now utilizes SMT technology.

3. **Superior High-Frequency Characteristics and Reliable Performance**

Chip components are securely mounted with either leadless or very short leads, minimizing parasitic inductance and capacitance. This improves high-frequency characteristics and reduces electromagnetic and radio frequency interference. Circuits designed with SMC and SMD can reach frequencies up to 3 GHz, compared to just 500 MHz for traditional components, which shortens transmission delay. For circuits with clock frequencies above 16 MHz, MCM technology can enable computer workstations to achieve high-end clock frequencies of 100 MHz while reducing additional power consumption from parasitic reactance by 2-3 times.

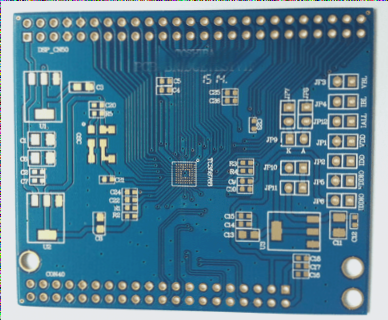

4. **Improve Productivity and Achieve Automated Production**

To fully automate the production of perforated mounting printed circuit boards, it is necessary to increase the PCB area by 40%. This expansion accommodates the insertion head of the automatic plug-in machine, which is essential for inserting electronic components. Without this extra space, there may be insufficient clearance, leading to potential damage to the parts. Automatic placement machines (SM421/SM411) utilize vacuum nozzles to pick and place electronic components. These nozzles are smaller than the components they handle, which enhances the density of component installation. Automatic placement machines are particularly effective for handling small electronic components and fine-pitch QFP devices, facilitating comprehensive automated production.

5. **Reduce Costs and Lower Expenses**

(1) The use area of the printed circuit board is reduced, with the area being 1/12 of that required by through-hole technology. Selecting CSP (Chip Scale Package) for installation significantly decreases this area.

(2) The number of holes in printed circuit boards is reduced, resulting in substantial savings on rework costs.

(3) Enhanced frequency characteristics lead to a significant reduction in circuit debugging costs.

(4) The small size and lightweight nature of chip components substantially cut down packaging, transportation, and storage costs.

SMT (Surface-Mount Technology) processing can greatly reduce costs by saving on materials, energy, equipment, and labor, potentially lowering overall costs by 30% to 50%.

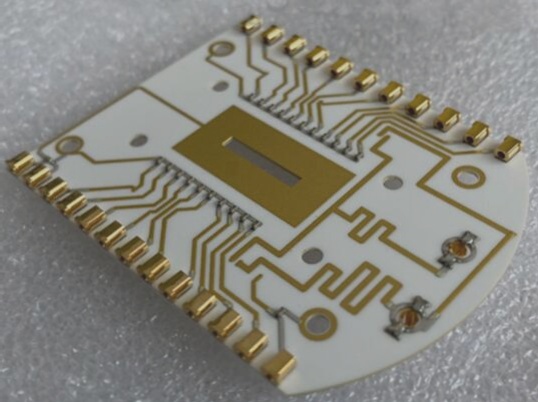

**PCB Circuit Board Substrate Material Classification**

The substrate is the foundational material used in PCB circuit board production. Typically, a PCB substrate consists of resin, reinforcing materials, and conductive materials. Common resins include epoxy resin and phenolic resin. Reinforcing materials can be paper-based or glass cloth, while copper foil is the standard conductive material. Copper foil comes in two types: electrolytic copper foil and rolled copper foil.

**PCB Substrate Material Classification:**

1. **According to Different Reinforcing Materials:**

1. Paper substrate (FR-1, FR-2, FR-3)

2. Epoxy glass fiber cloth substrate (FR-4, FR-5)

3. Composite substrate (CEM-1, CEM-3, Composite Epoxy Material Grade-3)

4. HDI (High-Density Interconnect) PCB sheet (RCC)

5. Special substrates (metal substrates, ceramic substrates, thermoplastic substrates, etc.)

2. **According to Flame Retardant Performance:**

1. Flame-retardant type (UL94-V0, UL94-V1)

2. Non-flame retardant type (UL94-HB grade)

3. **According to Different Resins:**

1. Phenolic resin PCB board

2. Epoxy resin PCB board

3. Polyester resin PCB board

4. BT resin PCB board

5. PI resin PCB board

1. **Smaller Size and Higher Installation Density**

SMT chip electronic components are approximately 10% the size of traditional components and weigh about 10% as much. SMT technology can reduce electronic equipment size by 40% to 60% and its mass by 60% to 80%, significantly decreasing both area and weight. The grid for SMT components has evolved from 1.27mm to 0.63mm, with some reaching 0.5mm. Through-hole installation technology can further enhance relative density.

2. **High Reliability and Enhanced Anti-Vibration Ability**

SMT chip components offer high reliability, compact size, lightweight, and strong anti-vibration capabilities. Automated production leads to high installation reliability, with defect rates in solder joints usually below 10 parts per million. In contrast, the defect rate in wave soldering for through-hole components is significantly higher, leading to lower overall reliability. As a result, nearly 90% of electronic equipment now utilizes SMT technology.

3. **Superior High-Frequency Characteristics and Reliable Performance**

Chip components are securely mounted with either leadless or very short leads, minimizing parasitic inductance and capacitance. This improves high-frequency characteristics and reduces electromagnetic and radio frequency interference. Circuits designed with SMC and SMD can reach frequencies up to 3 GHz, compared to just 500 MHz for traditional components, which shortens transmission delay. For circuits with clock frequencies above 16 MHz, MCM technology can enable computer workstations to achieve high-end clock frequencies of 100 MHz while reducing additional power consumption from parasitic reactance by 2-3 times.

4. **Improve Productivity and Achieve Automated Production**

To fully automate the production of perforated mounting printed circuit boards, it is necessary to increase the PCB area by 40%. This expansion accommodates the insertion head of the automatic plug-in machine, which is essential for inserting electronic components. Without this extra space, there may be insufficient clearance, leading to potential damage to the parts. Automatic placement machines (SM421/SM411) utilize vacuum nozzles to pick and place electronic components. These nozzles are smaller than the components they handle, which enhances the density of component installation. Automatic placement machines are particularly effective for handling small electronic components and fine-pitch QFP devices, facilitating comprehensive automated production.

5. **Reduce Costs and Lower Expenses**

(1) The use area of the printed circuit board is reduced, with the area being 1/12 of that required by through-hole technology. Selecting CSP (Chip Scale Package) for installation significantly decreases this area.

(2) The number of holes in printed circuit boards is reduced, resulting in substantial savings on rework costs.

(3) Enhanced frequency characteristics lead to a significant reduction in circuit debugging costs.

(4) The small size and lightweight nature of chip components substantially cut down packaging, transportation, and storage costs.

SMT (Surface-Mount Technology) processing can greatly reduce costs by saving on materials, energy, equipment, and labor, potentially lowering overall costs by 30% to 50%.

**PCB Circuit Board Substrate Material Classification**

The substrate is the foundational material used in PCB circuit board production. Typically, a PCB substrate consists of resin, reinforcing materials, and conductive materials. Common resins include epoxy resin and phenolic resin. Reinforcing materials can be paper-based or glass cloth, while copper foil is the standard conductive material. Copper foil comes in two types: electrolytic copper foil and rolled copper foil.

**PCB Substrate Material Classification:**

1. **According to Different Reinforcing Materials:**

1. Paper substrate (FR-1, FR-2, FR-3)

2. Epoxy glass fiber cloth substrate (FR-4, FR-5)

3. Composite substrate (CEM-1, CEM-3, Composite Epoxy Material Grade-3)

4. HDI (High-Density Interconnect) PCB sheet (RCC)

5. Special substrates (metal substrates, ceramic substrates, thermoplastic substrates, etc.)

2. **According to Flame Retardant Performance:**

1. Flame-retardant type (UL94-V0, UL94-V1)

2. Non-flame retardant type (UL94-HB grade)

3. **According to Different Resins:**

1. Phenolic resin PCB board

2. Epoxy resin PCB board

3. Polyester resin PCB board

4. BT resin PCB board

5. PI resin PCB board