Understanding Different Types of Test Fixtures in PCB Manufacturing

1. Compound Fixtures vs. Dedicated and Universal Fixtures

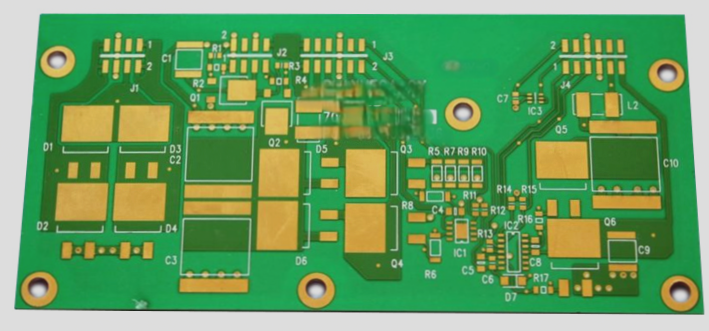

A compound fixture combines the features of dedicated and universal fixtures, offering flexibility and cost-effectiveness in testing. While dedicated fixtures cater to specific needs with enhanced capabilities, they come at a higher production cost. On the other hand, universal fixtures, like the traditional On Grid fixture, provide reusability and cost reduction benefits. However, with the shift towards surface mount designs in electronic components, the limitations of universal fixtures have become apparent.

2. Evolution of Test Fixtures with SMD Designs

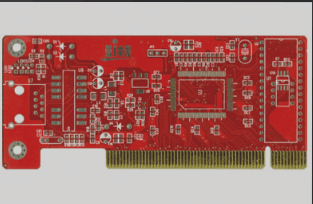

With the increasing adoption of surface mount (SMD) designs and higher contact density in electronic products, traditional universal fixtures are no longer sufficient to meet testing requirements. Double-density and four-density dial tests have emerged to address the demand for higher test densities. Specialized fixtures, known as Dedicated Fixtures, are now essential for testing high-density PCB circuit configurations, albeit at a higher production cost.

3. Future Trends in PCB Testing

While contact testing remains the industry standard due to reliability concerns, ongoing research is focused on developing non-contact testing methods. Despite the potential benefits of non-contact testing, such as with flying probe testers, the industry is still primarily reliant on contact testing for electrical testing. However, advancements in high-speed flying probes and non-contact electrical testing methods indicate the industry’s future direction towards more efficient and cost-effective testing solutions.

- Compound fixtures combine flexibility and cost-effectiveness.

- Dedicated fixtures cater to specific needs but come at a higher cost.

- Universal fixtures are no longer adequate for high-density SMD designs.

- Specialized Dedicated Fixtures are essential for testing high-density PCBs.

- Research is ongoing for non-contact testing methods.

- The industry is moving towards high-speed flying probes and non-contact testing for the future.