CNC Machining: A Comprehensive Overview

CNC (Computer Numerical Control) machining is a pivotal technology in modern manufacturing processes. It involves the utilization of a computer to direct and control machine tools throughout the production cycle.

When engaging in CNC machining, a Computer-Aided Design (CAD) file is first crafted and then imported into the CNC machine. Subsequently, G-code, a specialized language, is generated to oversee crucial aspects like feed rate, positioning, coordination, and speed.

Prior to commencing production, meticulous testing is imperative to validate the accuracy of the G-code in comparison to the original CAD design file.

Once the preparatory stages are finalized, the production phase initiates, with the material being loaded into the CNC machine. Noteworthy is that the machining process maintains consistency irrespective of the quantity of workpieces being manufactured.

For enhanced thermal and debris management, operators may apply cutting fluid to the machining tools during operations. This practice aids in averting tool damage due to overheating, thereby ensuring optimal tool performance.

The realm of CNC machining boasts numerous benefits, including unparalleled precision, the capacity to fabricate intricate shapes, and the ability to replicate processes with utmost accuracy. Tasks that are often arduous to execute manually are seamlessly accomplished through CNC machining, facilitating the seamless transformation of any 2D or 3D design into a top-tier finished product.

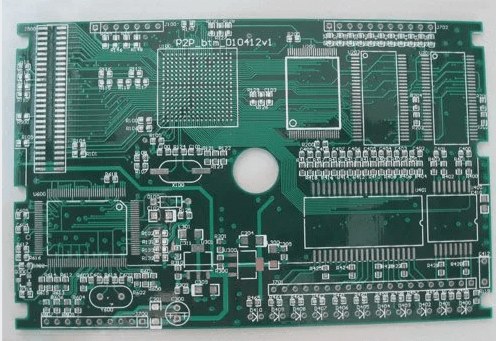

For inquiries concerning PCBs or PCBA, please don’t hesitate to reach out to us at info@wellcircuits.com