Key Points in PCBA Labor and Materials for Quality Assurance

-

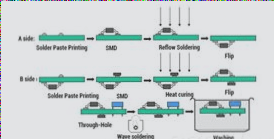

SMT Patch Processing

Quality control in solder paste printing and reflow soldering temperatures is crucial in PCBA manufacturing. Laser stencils are used for high-precision circuit boards, and steel mesh processing must align with PCBA technology specifications.

-

Temperature Control and AOI Testing

Reflow oven temperature accuracy and AOI testing are essential to minimize defects during SMT patch processing. Adherence to standard operating procedures is key to reducing human error-related defects.

-

DIP Plug-In Post Soldering

Designing the furnace jig for wave soldering is critical in this final processing stage. Utilizing the furnace fixture effectively can improve yield rates and reduce soldering defects.

-

Manufacturability Report and Testing

Conducting a manufacturability report before full production provides valuable insights. Establishing test points on the PCB and engaging in backend programming can enhance testing efficiency and product integrity.

-

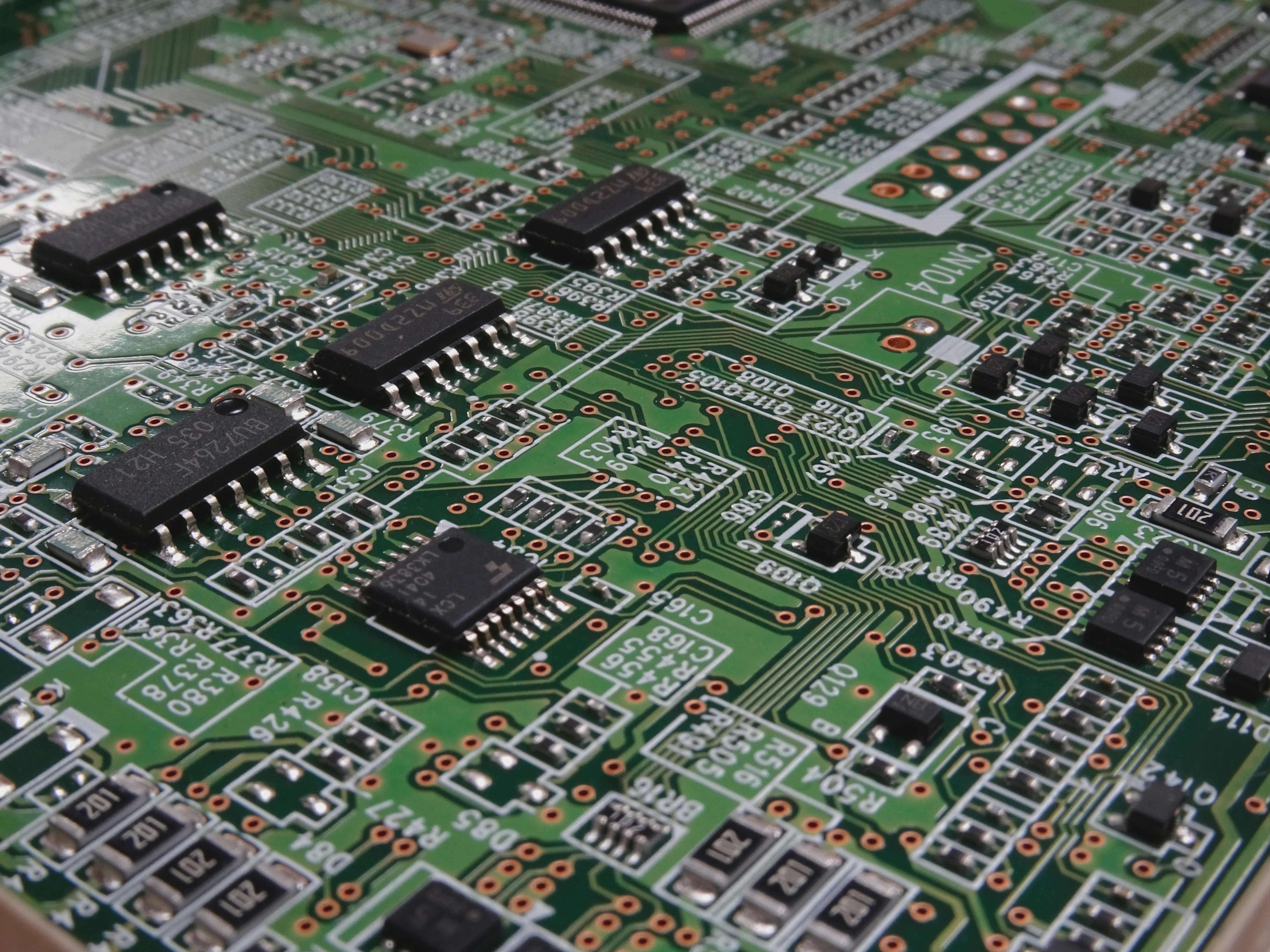

Back-End Testing

Customers often require comprehensive back-end testing for PCBA, including ICT, FCT, burn tests, temperature/humidity tests, and more to ensure product quality.

For further adjustments or inquiries, feel free to reach out!