Automatic PCB Path Detection Circuit Design

Introduction

In the field of reverse engineering and electronic equipment maintenance, understanding the interconnections between PCB components is crucial. Traditionally, engineers manually measure and record the relationships between component pins using a multimeter. However, this process is time-consuming, prone to errors, and limited in accuracy.

To address these challenges, a new approach involving an automated path detection circuit controlled by a microcontroller has been developed. This system streamlines the process of measuring, recording, and verifying component connections on a PCB.

This article explores the design concepts and technologies behind the path detection circuit, focusing on automatic measurements. The key functions of the circuit include selecting test pin pairs, determining the path relationship between pins, and recording measurement results.

Automatically Selecting and Measuring Pin Pairs

Automatic Switching of Measurement Pin Pairs

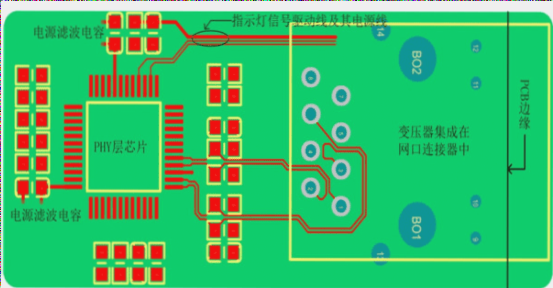

To facilitate the selection of different pins for measurement, a switch array controlled by programming is utilized. By activating specific switches, the component pins are integrated into the measurement path, allowing for the determination of their pass/break relationships.

Utilizing an analog multiplexer is essential for forming the switch array due to the analog nature of the voltage measurements.

Measurement of Pass/Break Relationship

The detection circuit design enables simultaneous measurement of the pass/break relationship between all connected pins, following the combination principle. This “in-fixture” measurement method ensures comprehensive testing of component pins within the test fixture.

In cases where a component pin is not clamped, a test pen is used for measurement. This “stylus measurement” involves connecting the pen to an analog channel and grounding the other end, allowing for precise measurements.

Measurement Voltage (VA)

Measurement Voltage and Threshold Determination in PCB Testing

When using VA as the measurement voltage in PCB testing, a voltage of 0 indicates a path, while a voltage greater than 0 suggests an interruption. The value of VA depends on the resistance between the measurement channels. Due to the conductive resistance (RON) of the analog multiplexer, VA will not be zero but equal to the voltage drop across RON once the measurement path is established.

To determine the pass/break relationship, a voltage comparator is used to check if VA exceeds the voltage drop across RON. Setting the threshold voltage of the comparator to match the voltage drop across RON allows for the direct reading of the digital measurement result by the microcontroller.

Determination of Threshold Voltage

RON varies with temperature and between devices, requiring the individual setting of the threshold voltage by closing analog switch channels. This can be achieved using a D/A converter. By cycling through switch pairs and incrementing the output of the voltage comparator, the threshold data can be easily determined for each channel path.

Dynamic Setting of Threshold Voltage

A table can be constructed using the collected threshold data. During in-fixture measurements, the corresponding data can be retrieved from the table based on the closed switch numbers, and the threshold voltage can be sent to the D/A converter.

For pen-clamp and pen measurements, only the threshold data for the specific switch needs to be loaded. Correcting the threshold voltage for inherent circuit errors and contact resistances ensures accurate identification of paths and prevents misclassification. The correction should be set reasonably based on actual conditions to account for small resistances between pins.

Through extensive PCB testing experiments, the testing circuit can accurately detect resistances above 5 ohms between pins, surpassing the accuracy levels of a typical multimeter.