1. Lidar is a type of active detection method that utilizes light waves for measurement.

2. Unlike passive detection methods such as cameras, which rely on ambient light for signal acquisition, active detection involves the measurement of signals through the reception of their echo signals.

3. Lidar calculates the distance between obstacles by measuring the time it takes for the laser to be reflected by the obstacle and received by the sensor.

Characteristics of Lidar PCB

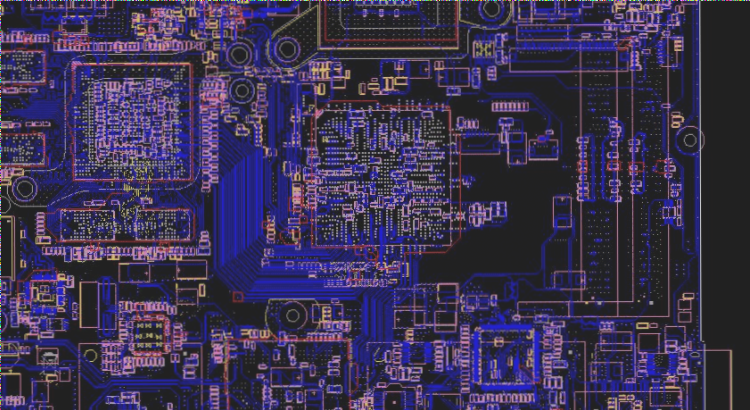

The Lidar PCB plays a crucial role in Lidar technology.

1. High precision

The performance of the laser radar PCB in high precision is outstanding. The detection accuracy of Lidar mainly depends on the accuracy of the PCB manufacturing process. The laser radar PCB requires high layout accuracy of each layer of the circuit, precise positioning of traction perforation holes, minimal number of circuit board layers, and stable PCB thickness to ensure the accuracy of laser emission and detection. At the same time, using advanced PCB design software, high-precision CNC machine tools, and advanced technology can improve the manufacturing accuracy of PCBs and further enhance the detection accuracy of Lidar.

2. High speed

In practical applications, laser radar requires high-speed scanning to obtain high-precision three-dimensional spatial information. Therefore, the laser radar PCB needs to have high-speed transmission and signal processing capabilities. In the design process, signal lines should be reasonably arranged, high-speed line design technology should be adopted, the structure and number of layers of PCB should be optimized, the delay and distortion of signal transmission should be reduced, and the data transmission rate should be improved to meet the needs of high-speed scanning of Lidar.

3. High reliability

Lidar requires long-term continuous operation in practical applications, which requires high reliability of PCBs. The laser radar PCB should minimize issues such as leakage, short circuit, distortion, and deformation of the circuit board while increasing the coupling ability between the circuit boards by increasing the connection points between the boards. In the manufacturing process, high-quality materials should be used, the manufacturing process should be optimized, and strict quality control should be carried out to ensure the high reliability of the Lidar PCB in the application process.

4. Multi-layered design

To meet the application requirements of Lidar, the design of Lidar PCB usually adopts a multi-layer board design. Multilayer PCBs can increase the density of circuit boards, reduce electromagnetic interference and noise, increase the layout space of circuits such as power lines and grounding wires, and also facilitate the separation of analog/digital and power supply layouts. When selecting multi-layer PCBs, it is necessary to choose appropriate parameters such as board thickness and copper thickness, while also avoiding issues such as small interlayer spacing between boards as much as possible to ensure the reliability and performance of Lidar PCBs in multi-layer design.

Differences between Lidar and Millimeter Wave Radar

1) Compared with microwave radar, Lidar has high resolution, good concealment, strong resistance to active interference, good low altitude detection performance, small size, and lightweight. The main drawback of Lidar is that it is greatly affected by weather and atmosphere during operation. Under severe weather conditions such as heavy rain, thick smoke, and fog, attenuation increases sharply and the propagation distance is greatly affected. Secondly, due to the extremely narrow beam of Lidar, it is very difficult to search for targets in space and can only search and capture targets within a small range.

2) Comparison of sensor performance

Resolution: Camera has the highest resolution, followed by Lidar, and millimeter wave radar has the lowest resolution

Weather resistance: Millimeter wave thunder is the best, followed by cameras, and Lidar is the lowest

Ability to track object speed: Millimeter wave thunder is the best, and the camera is similar to Lidar

Ability to track object height: Lidar is the best, followed by cameras, and millimeter wave thunder is the lowest

Tracking distance capability: Lidar and millimeter wave thunder are both very accurate, with the lowest camera

Distinguishing ability: Both cameras and Lidar are good, but millimeter wave thunder is lower.

Lidar PCB can measure distance more accurately and quickly than traditional radar technology, and it can also measure the speed and direction of objects, as well as provide more information.

For more information, click the website: wellcircuits.com

To enhance Your Business Efficiency, contact us:

To discover How Our Solutions Can Help Your Business, contact us:

Stay Ahead in Your Industry – Subscribe to Our Latest News

Customized Solutions Await Discovery – Contact Our Sales Team

Don’t Miss Critical Updates – Subscribe to us now

2. Unlike passive detection methods such as cameras, which rely on ambient light for signal acquisition, active detection involves the measurement of signals through the reception of their echo signals.

3. Lidar calculates the distance between obstacles by measuring the time it takes for the laser to be reflected by the obstacle and received by the sensor.

Characteristics of Lidar PCB

The Lidar PCB plays a crucial role in Lidar technology.

1. High precision

The performance of the laser radar PCB in high precision is outstanding. The detection accuracy of Lidar mainly depends on the accuracy of the PCB manufacturing process. The laser radar PCB requires high layout accuracy of each layer of the circuit, precise positioning of traction perforation holes, minimal number of circuit board layers, and stable PCB thickness to ensure the accuracy of laser emission and detection. At the same time, using advanced PCB design software, high-precision CNC machine tools, and advanced technology can improve the manufacturing accuracy of PCBs and further enhance the detection accuracy of Lidar.

2. High speed

In practical applications, laser radar requires high-speed scanning to obtain high-precision three-dimensional spatial information. Therefore, the laser radar PCB needs to have high-speed transmission and signal processing capabilities. In the design process, signal lines should be reasonably arranged, high-speed line design technology should be adopted, the structure and number of layers of PCB should be optimized, the delay and distortion of signal transmission should be reduced, and the data transmission rate should be improved to meet the needs of high-speed scanning of Lidar.

3. High reliability

Lidar requires long-term continuous operation in practical applications, which requires high reliability of PCBs. The laser radar PCB should minimize issues such as leakage, short circuit, distortion, and deformation of the circuit board while increasing the coupling ability between the circuit boards by increasing the connection points between the boards. In the manufacturing process, high-quality materials should be used, the manufacturing process should be optimized, and strict quality control should be carried out to ensure the high reliability of the Lidar PCB in the application process.

4. Multi-layered design

To meet the application requirements of Lidar, the design of Lidar PCB usually adopts a multi-layer board design. Multilayer PCBs can increase the density of circuit boards, reduce electromagnetic interference and noise, increase the layout space of circuits such as power lines and grounding wires, and also facilitate the separation of analog/digital and power supply layouts. When selecting multi-layer PCBs, it is necessary to choose appropriate parameters such as board thickness and copper thickness, while also avoiding issues such as small interlayer spacing between boards as much as possible to ensure the reliability and performance of Lidar PCBs in multi-layer design.

Differences between Lidar and Millimeter Wave Radar

1) Compared with microwave radar, Lidar has high resolution, good concealment, strong resistance to active interference, good low altitude detection performance, small size, and lightweight. The main drawback of Lidar is that it is greatly affected by weather and atmosphere during operation. Under severe weather conditions such as heavy rain, thick smoke, and fog, attenuation increases sharply and the propagation distance is greatly affected. Secondly, due to the extremely narrow beam of Lidar, it is very difficult to search for targets in space and can only search and capture targets within a small range.

2) Comparison of sensor performance

Resolution: Camera has the highest resolution, followed by Lidar, and millimeter wave radar has the lowest resolution

Weather resistance: Millimeter wave thunder is the best, followed by cameras, and Lidar is the lowest

Ability to track object speed: Millimeter wave thunder is the best, and the camera is similar to Lidar

Ability to track object height: Lidar is the best, followed by cameras, and millimeter wave thunder is the lowest

Tracking distance capability: Lidar and millimeter wave thunder are both very accurate, with the lowest camera

Distinguishing ability: Both cameras and Lidar are good, but millimeter wave thunder is lower.

Lidar PCB can measure distance more accurately and quickly than traditional radar technology, and it can also measure the speed and direction of objects, as well as provide more information.

For more information, click the website: wellcircuits.com

To enhance Your Business Efficiency, contact us:

To discover How Our Solutions Can Help Your Business, contact us:

Stay Ahead in Your Industry – Subscribe to Our Latest News

Customized Solutions Await Discovery – Contact Our Sales Team

Don’t Miss Critical Updates – Subscribe to us now