Printed Circuit Boards: Rigid vs. Flexible

Printed circuit boards (PCBs) are categorized into two main types based on production materials: rigid printed boards and flexible printed boards.

Rigid Printed Boards

- Phenolic paper laminates

- Epoxy paper laminates

- Polyester glass sensor boards

- Epoxy glass laminates

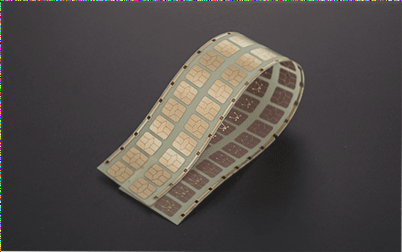

Flexible Printed Circuit Boards (FPC)

FPC is a highly reliable and flexible circuit board made from polyimide or polyester film. Here are some key advantages of FPC:

- Small volume and light weight

- Movable and bendable

- Excellent dielectric properties and heat resistance

- High assembly reliability and easy operation

- Ability to achieve three-position connection installation

- Enhanced heat conduction

- 7% cost reduction

- Good processing continuity

Advantages of Flexible Printed Circuit Boards

- Compact and lightweight design

- High flexibility for bending, twisting, and folding

- Excellent electrical properties and high-temperature resistance

- Substantial assembly reliability and reduced assembly workload

- Increased strength with reinforcing materials

- High density and reliability

- Standardized and optimized properties through design protocols

Additional Information

- Modern management practices ensure productive and standardized production

- Comprehensive testing methods guarantee product quality and lifespan

- Automatic insertion of electronic components enhances quality and efficiency

- Distinct differences between rigid and flexible circuit boards

- Considerations for current-carrying capacity, shape, and flexibility