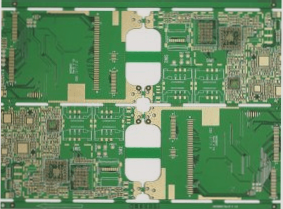

The Advantages of Immersion Gold PCB Boards Over Gold-Plated PCB Boards

- Immersion gold PCB boards have a thicker crystal structure compared to gold-plated boards, resulting in a more visually appealing golden yellow appearance.

- Immersion gold allows for easier welding, reducing the chances of poor welding and customer complaints. It also offers more manageable stress, making it beneficial for products requiring bonding processes.

- With immersion gold boards, signal transmission remains efficient as nickel-gold is only present on the pad, keeping the skin effect within the copper layer.

- Immersion gold has a denser crystal structure and is less prone to oxidation than gold plating.

- Gold plating may lead to short circuits in densely packed wiring, while immersion gold boards prevent such issues with nickel-gold only on the pad.

- The combination of solder mask and copper layer on immersion gold boards is stronger, ensuring uncompromised spacing.

- Immersion gold is preferred for high-quality boards with superior flatness, reducing the occurrence of the black pad phenomenon after assembly.

Overall, immersion gold PCB boards offer various advantages over gold-plated boards, making them a preferred choice for products with high-quality requirements and precise applications.