**What are the methods of special electroplating in PCB production?**

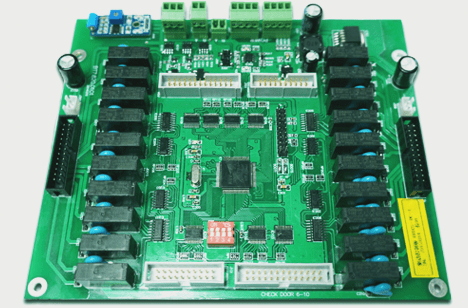

1. **Finger Row Type Electroplating Equipment**

In electroplating, it is often necessary to deposit rare metals on board edge connectors, protruding contacts, or gold fingers to achieve lower contact resistance and enhanced wear resistance. This technique is referred to as finger row electroplating or protruding part electroplating.

Typically, gold is applied to the protruding contacts of the edge connector over a nickel inner plating layer. The electroplating of gold fingers or protruding parts can be conducted using either manual or automatic techniques. Currently, gold plating on contact plugs or gold fingers has been replaced by lead and plated buttons.

2. **PCB Through-Hole Plating**

Through-hole electroplating encompasses various methods to establish a layer of electroplating on the walls of drilled holes in the substrate, a process known as hole wall activation in industrial applications. The commercial production of printed circuits necessitates multiple intermediate storage tanks, each requiring specific control and maintenance procedures.

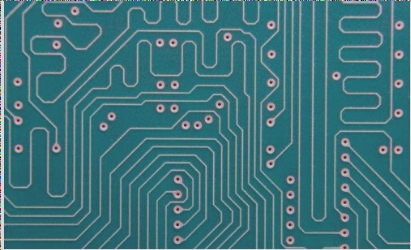

1. Through-hole plating is an essential follow-up process to drilling. When the drill bit penetrates the copper foil and the underlying substrate, the heat generated melts the insulating synthetic resin that predominantly makes up the substrate matrix. This molten resin, along with other drilling debris, accumulates around the hole and coats the newly exposed hole wall in the copper foil.

2. This phenomenon can negatively impact the subsequent electroplating surface of the PCB. The molten resin leaves a layer of hot residue on the substrate hole wall, exhibiting poor adhesion to most activators. Consequently, this necessitates the development of another technology akin to stain removal and etch-back chemistry: the use of ink!

3. The ink is applied to create a highly adhesive and conductive film on the inner wall of each through-hole, eliminating the need for multiple chemical treatments. With just a single application step followed by heat curing, a continuous film forms on the interior surfaces, allowing for direct electroplating without further processing. This resin-based ink adheres strongly to the walls of most thermally polished holes, thus removing the etch-back step.

4. Selective plating with reel linkage is commonly employed for the pins of PCB electronic components, such as connectors, integrated circuits, transistors, and flexible printed circuits, to achieve optimal contact resistance and corrosion resistance.

5. This electroplating method can utilize either manual production lines or automated equipment. Individually selecting and plating each pin can be quite costly, necessitating the use of batch processing. In electroplating production, the metal foil is typically rolled to the desired thickness, with both ends punched and cleaned through chemical or mechanical methods, followed by selective continuous electroplating using materials such as nickel, gold, silver, rhodium, tin-nickel alloy, copper-nickel alloy, and nickel-lead alloy.

6. Brush plating is another technique, known as “brush plating,” where not all parts are immersed in the electrolyte during the electroplating process. In this method, only a specific area is electroplated, leaving the rest unaffected.

7. Comparing circuit board PTH to plastic plating reveals some key differences. While plastic electroplated products achieve an appealing metal finish and reduce product weight, they also enhance electrical, thermal, and corrosion resistance, thereby improving the mechanical strength of the surface.

8. Many individuals may not distinguish between plastic plating and circuit board PTH. Plastic electroplating differs from PCB PTH electroplating; the circuit board PTH process is a type of plastic electroplating that primarily involves depositing a catalyst on the plastic surface, followed by metal electroplating to thicken the deposited layer.

9. The general pre-treatment for plastic electroplating includes roughening the surface, depositing the catalyst, precipitating conductive metal, thickening the electroplating, and applying rust prevention or passivation treatments. While these basic procedures are similar across different fields, adjustments are made according to specific product quality requirements.

10. Both technologies have their drawbacks. In the early umbrella industry, graphite was applied to the front end of the umbrella cap to create a conductive layer before metal electroplating. However, the metal film often peeled off due to inadequate pre-processing, despite its low cost. Similar applications are found in current sanitary equipment, such as faucet knobs and washbasin accessories.

11. The introduction of alloy catalyst fluids has revolutionized traditional electroplating technology! A new generation of environmentally friendly special surface alloy catalyst fluids has emerged, opening a new era in metal surface treatment. This technology employs chemical displacement reactions to interact with the workpiece, forming a new alloy layer that is resistant to peeling and flaking, with very stable performance. The alloy catalyst fluid is characterized by its environmentally friendly nature, simplicity of process, and low cost, making it widely applicable across various fields.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me