1. **Nowadays, PCB design is widely used in various industries.** From communication equipment to medical devices, from small mobile phones to the Tiangong Shenzhou spacecraft in space.

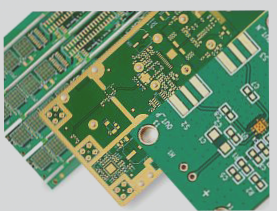

2. **A rigid circuit board, known as a PCB (Printed Circuit Board),** is an essential electronic component that serves as a support for electronic components and a carrier for their electrical connections. As it is produced through electronic printing, it is referred to as a “printed” circuit board.

3. **FPC, or Flexible Printed Circuit Board,** is a type of printed circuit made from a flexible insulating substrate. Flexible circuits offer excellent electrical performance, meeting the demands of smaller and higher-density designs. They also reduce assembly steps and improve overall reliability. Flexible circuit boards are the ideal solution to address the miniaturization and mobility needs of modern electronic devices. They can bend, twist, and fold without damaging the wiring, and can endure millions of dynamic flexing cycles. This flexibility allows them to be arranged according to specific spatial requirements, enabling three-dimensional movement and expansion. This integration of component assembly and wiring connection helps significantly reduce the size and weight of electronic products, making flexible circuits crucial for the development of high-density, miniaturized, and highly reliable electronics.

Because rigid and flexible PCBs serve different purposes, their design approaches differ significantly. So, what factors should be considered during the design process?

**Flexibility**

Using thinner laminates and wider traces increases the likelihood of withstanding repeated bending cycles. For applications involving frequent bending, single-sided flexible PCBs generally perform better.

**Pads**

The area around the pad transitions from flexible to rigid material, making it more susceptible to conductor damage. Therefore, pads should be avoided in regions that experience frequent bending.

**Traces**

Flexible PCBs typically have poor heat dissipation capabilities, so trace widths should be designed to be sufficiently wide to handle the current without overheating.

**Shape**

Inner corners should be rounded to prevent the board from tearing. Traces that connect to plated through holes or component mounting holes should smoothly transition into the pad. Any change in direction or trace width should be gradual. Sharp corners can concentrate stress and lead to trace failure.

In summary, when designing flexible PCBs, the following points should be considered:

1. The three-dimensional space of the flexible printed circuit is crucial, as bending and flexibility can help save space and reduce the number of board layers.

2. Compared to rigid PCBs, flexible boards have lower tolerance requirements and a wider range of acceptable variations.

3. Since flexible PCBs can bend, they are often designed to be slightly longer than necessary to accommodate the bending process.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me