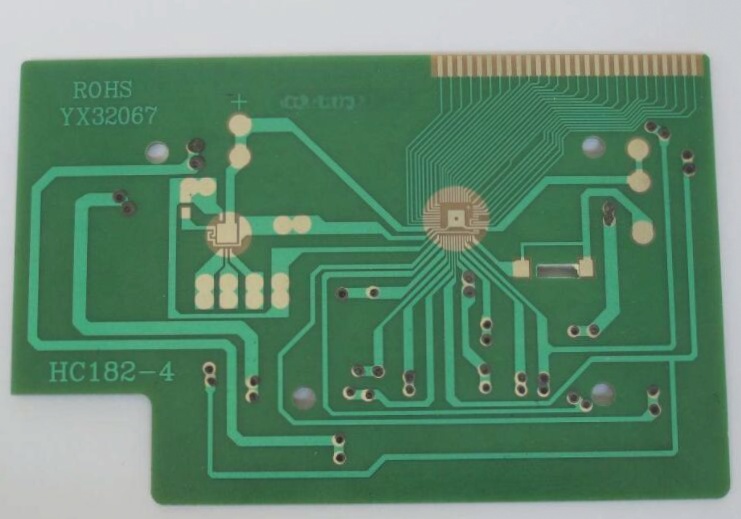

The Significance of PCB Board Colors

Have you ever wondered why PCB boards come in different colors? Let’s delve into the secrets behind the colors you see on PCB boards.

1. Importance of Green Color

Green is the most commonly used color for PCB boards due to its cost-effectiveness and long-standing tradition in the industry. Manufacturers often choose green for its practicality and reliability.

2. Role of Colors in Manufacturing Process

During the PCB manufacturing process, the choice of color can impact various stages such as board fabrication and SMT processes. Green is preferred for its visibility under specific lighting conditions and its assistance in optical positioning during solder paste application and component placement.

3. Eye-Friendly Green PCBs

Green PCBs are favored by manufacturers for their eye-friendly properties, especially during quality inspection processes that require prolonged exposure to bright light. The color green is less straining on the eyes compared to other colors, making it a popular choice in the industry.

4. Blue and Black PCBs

Blue and black PCBs contain elements like cobalt and carbon, affecting their electrical conductivity and susceptibility to short-circuits. Green PCBs, on the other hand, are environmentally friendly and do not emit toxic gases during operation.

5. Industry Trends and Preferences

Since the latter half of the last century, the color of PCBs has gained significance in the industry. Green PCBs are often associated with premium products, reflecting a shift in consumer perception towards this color choice.

Conclusion

While red, yellow, blue, and black PCBs are common, green remains the preferred choice for manufacturers due to its practicality, visibility, and eye-friendly properties. The color of a PCB board plays a significant role in various manufacturing processes and can impact the overall quality of the product.