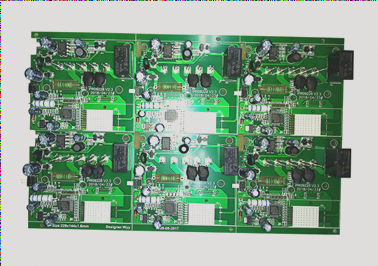

PCB Multilayer Board Design

Signal Layers

- Altium Designer supports up to 32 signal layers in a multilayer PCB, including Top Layer, Bottom Layer, and Mid-Layers interconnected via through vias, blind vias, and buried vias.

- Top Layer: Used for component placement, signal traces, and heat dissipation.

- Bottom Layer: Mainly for signal traces, solder pads, and SMD component placement.

- Mid-Layers: Create additional signal layers for high-density routing and performance optimization.

Internal Planes

Internal planes carry power and ground traces, reducing signal noise and ensuring stable power distribution in a multilayer PCB.

Inner Electric Layers

Inner electric layers in a multilayer PCB create electrical connections between signal layers, enhancing routing flexibility.

Silkscreen Layers

PCB silkscreen layers, including Top and Bottom Overlay, provide labeling and annotation for component placement and circuit inspection.

Top Overlay

Markings on the Top Overlay layer indicate component outlines and labels for easy assembly.

Bottom Overlay

The Bottom Overlay layer mirrors the top silkscreen for component identification on the bottom side of the board.

Mechanical Layers

Mechanical layers store manufacturing and assembly details like board dimensions and component shapes for fabrication.

Key Mechanical Layers:

- Mechanical 1: Defines the PCB’s mechanical outline or shape.

- Mechanical 2: Specifies process requirements and material details.

- Mechanical 13 & Mechanical 15: Include 3D component body information for accurate representation.

Mechanical 16: Footprint Information for PCB Components

This layer, Mechanical 16, stores the footprint information of components from the ETM library. It is a valuable resource for estimating the overall size of the PCB during the early design phase. Similar to Mechanical 13 and 15, it is initially hidden to maintain design clarity.

Mask Layers in Altium Designer

Altium Designer features two primary types of mask layers: the Solder Mask and the Paste Mask. These layers play essential roles in protecting and preparing the PCB surface.

Solder Mask

The solder mask is applied to areas of the PCB where soldering is unnecessary, helping to prevent unintended solder bridges during assembly. Both the top and bottom layers of the PCB typically have solder mask coverage.

Paste Mask

The paste mask is specifically designed to outline where solder paste should be applied during the Surface Mount Technology (SMT) assembly process. Similar to the solder mask, paste masks are designated for both the top and bottom sides of the PCB, although they may not always be visible by default in design layouts.