Advancements in Automotive Electronics and PCB Manufacturing

In today’s fast-paced world, automotive electronics are constantly evolving, with new ideas and innovations emerging daily. Technologies like autonomous vehicles, electric vehicles (EVs), and hybrid electric vehicles have revolutionized the automotive industry, driving the need for miniaturization and robust electronic solutions. Safety is now a top priority for manufacturers and OEMs.

The Role of Conformal Coatings in Automotive PCBs

Conformal coatings are essential for enhancing the performance of PCBs in automotive electronics. These coatings protect components from environmental stresses like moisture and dust, increasing durability and longevity.

Key Factors Driving PCB Manufacturing in Automotive Electronics

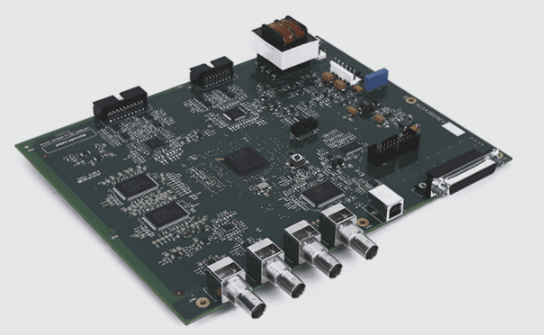

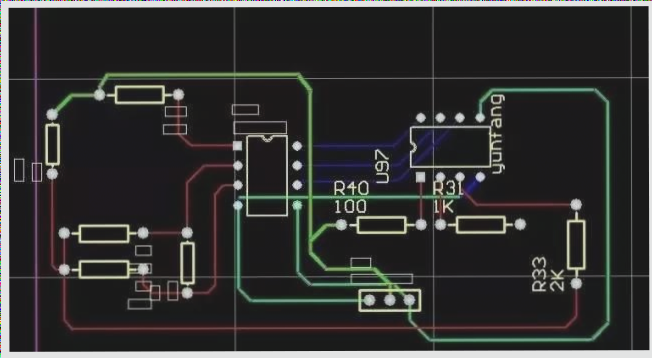

The demand for advanced technologies in vehicles is rising, with features like automatic parking systems and driver assistance systems becoming standard. PCBs play a critical role in meeting these high standards for reliability and performance.

As electronic systems in vehicles expand, ensuring the safety of components is crucial. Choosing the right PCB is a complex challenge for OEMs, as it directly impacts the performance of automotive electronics.

The Significance of Conformal Coatings for PCB Assembly

Conformal coatings provide electrical insulation and shield PCBs from environmental stresses. These coatings enhance durability and protect PCBs from moisture, thermal fluctuations, pollutants, and corrosive substances, ensuring vehicle safety and reliability.

Understanding Conformal Coating Applications

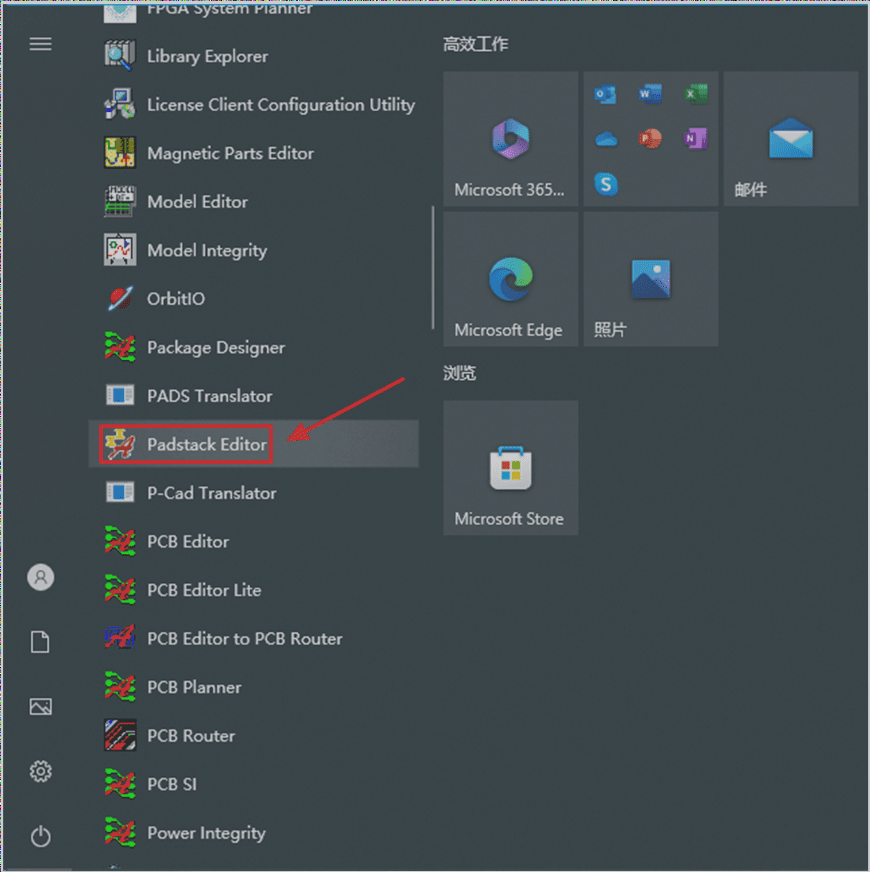

Conformal coatings are thin polymer layers applied to PCBs, offering robust protection in minimal space. Various application methods, such as robotic dispensing and spraying, can be used based on production scale.

Addressing Industry Challenges: Tin Whiskers and Mechanical Support

Protecting Automotive PCBs with Conformal Coatings

In the realm of automotive electronics, the use of lead-free components has given rise to a concern known as “tin whiskers.” These tiny structures can form under thermal and mechanical strain, leading to short circuits. To combat this issue, conformal coatings are applied to PCBs, serving as a protective barrier against tin whisker growth and potential short circuits. Additionally, these coatings offer mechanical support that enhances solder joint fatigue resistance, ultimately extending the lifespan of the PCB.

The Crucial Role of Coatings in Automotive Control Systems

PCBs are crucial components in various automotive control systems, ranging from brake fluid sensors to engine management units. It is imperative to coat these PCBs adequately to ensure their reliability in challenging environments. However, the application of conformal coatings must not disrupt the vehicle manufacturing process. Therefore, selecting the right conformal coating solutions is essential for the safe and efficient operation of electronic systems in vehicles.

Choosing the Ideal Conformal Coating

Conformal coatings are available in different formulations tailored to specific applications. Varieties include polyurethane acrylate, silicone-based coatings, solvent-based formulas, and two-part epoxy resins. While light-curing coatings offer benefits, the selection of the most suitable coating depends on the PCB’s unique requirements. Collaborating with PCB manufacturers and experts is crucial for identifying the optimal coating that meets performance and protection standards for automotive PCBs.

Ensuring Quality through Qualification and Environmental Testing

Thorough qualification and environmental testing are essential to verify that the chosen coating is suitable for its intended purpose. These tests replicate real-world conditions such as temperature fluctuations, mechanical stress, moisture exposure, vibration, chemical resilience, and salt spray. Conducting comprehensive testing is vital in determining the most effective protective coating for automotive applications.

Enhancing Automotive Electronics with Conformal Coatings

Conformal coatings play a vital role in safeguarding modern automotive electronics against environmental challenges, enhancing durability, and optimizing overall PCB performance. Through meticulous coating selection and rigorous testing, manufacturers can guarantee that the next wave of automotive electronics maintains high standards of safety, reliability, and performance.