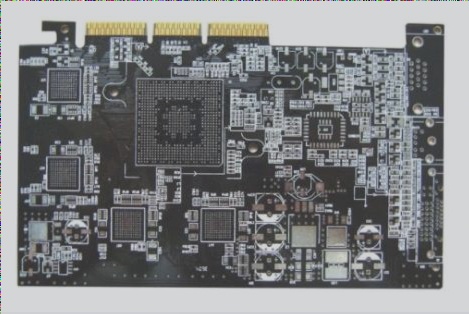

Key Materials for SMT Chip Processing

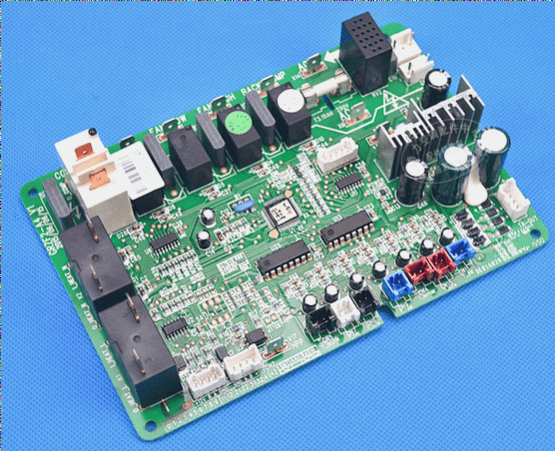

- Adhesive: Adhesive is crucial in SMT chip processing to bond components to the substrate, ensuring stability and reliability of solder joints.

- Cleaning Agent: Cleaning agent is essential for removing flux residues and contaminants from the PCB surface post-soldering, ensuring cleanliness and solder joint reliability.

- Heat Transfer Medium: Heat transfer medium aids in reflow soldering by providing uniform heat transfer to solder joints, minimizing defects.

Choosing the right process materials is vital for quality and efficiency in SMT chip processing. Each material serves a specific role, and proper selection and usage are key for high-quality and reliable SMT chip products.

Adhesive in SMT Patches

Adhesive is the bonding material used in SMT patches, pre-fixing components on the PCB during wave soldering. It enhances SMD fixation and prevents shifting during assembly.

Cleaning Agent Importance

Cleaning agents remove residue post-soldering, a critical step in SMT patches. Solvent cleaning remains the most effective method for ensuring cleanliness.

SMT processing materials are fundamental in the patch process, selected based on specific assembly requirements and processes.