The Importance of Bill of Materials (BOM) in Surface Mount Technology (SMT)

1. In the realm of electronics manufacturing, efficiency and reliability are paramount for success. The Bill of Materials (BOM) is a crucial document in Surface Mount Technology (SMT) processes, enhancing production efficiency, reducing errors, cutting costs, and optimizing operations.

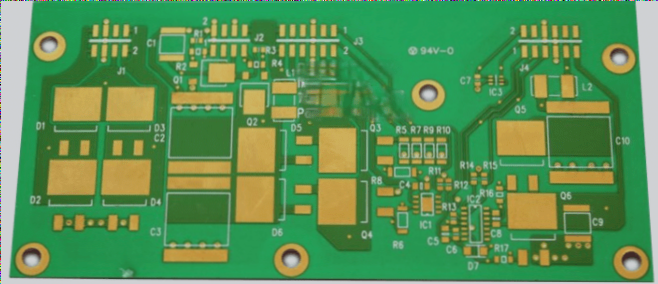

2. A BOM is a detailed list of all components, materials, and assemblies needed for product manufacturing. It includes part numbers, descriptions, quantities, and specifications. In SMT, the BOM acts as a blueprint for the entire manufacturing process, ensuring accurate component incorporation and minimizing errors and delays.

3. The BOM in SMT production plays key roles by sourcing parts correctly, providing assembly references for PCBs, and tracking component changes. It helps avoid shortages, align components accurately, and adapt to evolving technologies.

4. The accuracy of the BOM directly impacts SMT process efficiency and quality. Errors can lead to incorrect orders, production delays, or faulty products. Maintaining an updated and precise BOM is crucial for smooth operations and high-quality outputs.

5. In essence, the BOM is the foundation of successful SMT manufacturing, ensuring proper component selection, sourcing, and usage. Prioritizing BOM accuracy streamlines processes, minimizes waste, and enhances production timelines.

Summary:

The BOM is a vital tool in SMT, ensuring manufacturing efficiency and reliability by guiding the production process. Its precision influences outcomes, and keeping the BOM current is essential for error reduction, delay avoidance, and top-notch results.

Enhancing Production Process Accuracy

One key function of a component BOM is ensuring precision in production. Clear specifications prevent errors in PCB assembly, crucial in SMT where mistakes lead to delays, increased costs, and reduced efficiency.

Streamlining Procurement and Inventory Management

The BOM aids procurement by identifying correct parts and quantities, supporting better pricing and inventory control. Efficient procurement reduces lead times, minimizes downtime, and smooths manufacturing.

Optimizing Production Planning

Production planning relies on BOM details to schedule tasks, allocate resources, and manage workflow effectively. Knowing component needs and timelines helps create realistic schedules, avoiding delays and bottlenecks.

Ensuring Precision in SMT Assembly

The Importance of Bill of Materials (BOM) in PCB Manufacturing

When it comes to Surface Mount Technology (SMT), precision is key. Any errors in component placement can lead to defects in the final product, resulting in costly rework or even complete assembly scrapping. An accurate BOM plays a crucial role in minimizing errors by providing clear guidance on component selection and placement, ultimately improving manufacturing efficiency.

1. Enhancing Precision in Manufacturing

A precise BOM is vital for accurate component assembly, reducing the risk of misplacements and ensuring a higher yield in the production process. By following the BOM closely, manufacturers can minimize errors and enhance the overall quality of PCB assemblies.

2. Enabling Quality Control

Quality control is essential in electronics manufacturing, and the BOM serves as a key reference during inspection and testing. By cross-referencing the BOM with the physical assembly, quality assurance teams can verify component accuracy and adherence to specifications, enabling early detection of discrepancies and maintaining high product quality.

3. Supporting Maintenance and Repair

Throughout a product’s lifecycle, a detailed BOM aids in maintenance and repairs by helping technicians quickly identify components that require replacement or servicing. This capability is crucial in industries where downtime can lead to significant financial losses, ensuring efficient repairs and minimal disruptions.

4. Fostering Collaboration and Adaptability

The BOM promotes collaboration among manufacturing teams by providing a common reference point for design, engineering, production, and procurement departments. Additionally, in a rapidly changing electronics landscape, a well-maintained BOM allows manufacturers to adapt swiftly to design modifications and component updates, ensuring smooth production processes.

5. Driving Success in High-Precision Industries

In industries prioritizing precision, efficiency, and quality, a well-managed BOM is foundational for success. From optimizing procurement and quality control to supporting ongoing maintenance and facilitating agility in competitive environments, the BOM plays a strategic role in meeting the demands of modern electronics manufacturing.

Conclusion:

The Bill of Materials (BOM) is a critical element in PCB manufacturing, offering benefits across various stages of the production cycle. By providing accurate guidance, enhancing quality control, supporting collaboration, and driving success in high-precision industries, the BOM remains indispensable for manufacturers aiming to deliver top-quality products efficiently.