The Importance of Soldering in Hardware Development

When it comes to hardware development, the focus is often on principle, PCB design, and performance. However, the soldering process is a critical step that should not be overlooked. Soldering involves assembling components before the birth of a hardware product, and the quality of this process can significantly impact the final outcome.

Understanding the Significance of Soldering

As a beginner in electronic design, I initially viewed soldering as a means to connect components based on schematics and PCB layouts. Through guidance from experienced colleagues, I came to appreciate the importance of achieving a flat and smooth soldering surface on the circuit board.

Challenges and Solutions

Working with high-speed circuits requires attention to detail, including the use of the right amount of flux to ensure signal quality. During product debugging, unexpected signal level variations led to a thorough investigation. It is essential to reflect on work habits and seek assistance from others to overcome challenges.

Key Aspects of Soldering

- Welding Materials: solder, flux

- Welding Temperature: adjust according to device specifications

- Welding Environment: maintain a smoke-free workspace

- Protective Measures: prevent static electricity and solder splashes for safety

WellCircuits Limited: Your PCB Manufacturing Partner

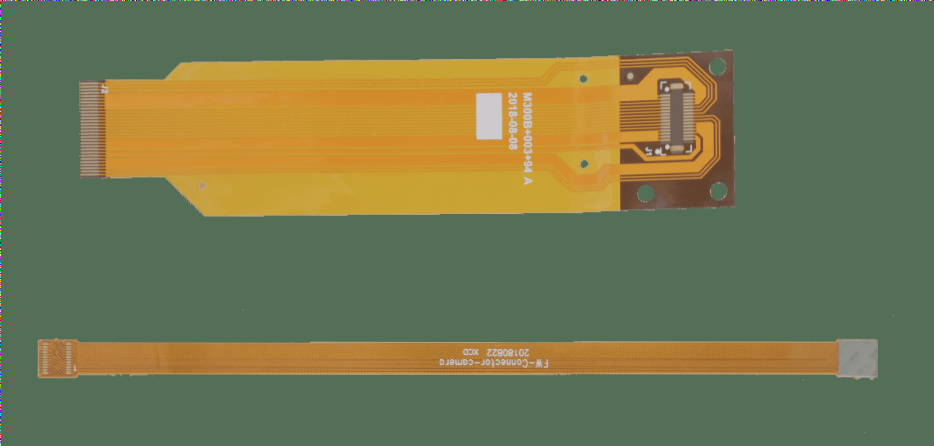

WellCircuits Limited specializes in producing high-precision PCBs, including double-sided, multilayer, and impedance-controlled boards. Our product range covers HDI, backplanes, rigid-flex, and more, meeting diverse customer needs.

For more information, visit WellCircuits PCB Fabrication and HDI PCB.