Generally, the basic process of designing a printed circuit board (PCB) can be divided into three main steps:

(1). **Circuit Schematic Design**

The circuit schematic is primarily designed and drawn using the PROTEL99 schematic design system (Advanced Schematic).

In this stage, it is important to fully utilize the various schematic drawing tools and editing features provided by PROTEL99 to ensure the creation of a correct and precise circuit schematic.

(2). **Generate Netlist**

The netlist serves as a bridge between the circuit schematic design (SCH) and the printed circuit board design (PCB). It acts as the “automatic” core of the PCB layout process.

The netlist can be generated from the schematic diagram or extracted from the PCB itself.

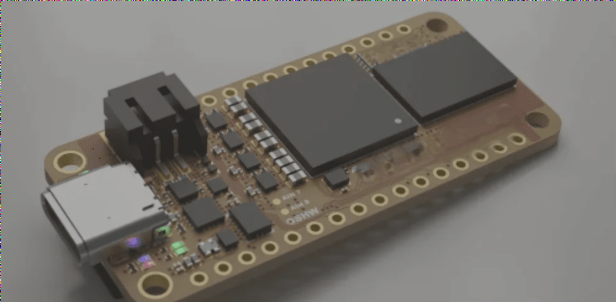

(3). **Printed Circuit Board Design**

The PCB design process focuses on another critical component of PROTEL99, specifically the PCB design module. In this stage, we leverage the powerful features of PROTEL99 to carry out the board layout and tackle the more challenging aspects of the design.

**2. Draw a Simple Circuit Diagram**

**2.1 Schematic Diagram Design Process**

The schematic design can be completed by following these steps:

1. **Design Drawing Size**

In Protel 99/Schematic, the first step is to define the overall part layout and determine the appropriate drawing size. The size should reflect the complexity of the circuit. Setting the correct drawing size is crucial for effective schematic design.

2. **Setting the Protel 99/Schematic Design Environment**

In this step, set up the Protel 99/Schematic environment. This includes adjusting parameters such as grid size, cursor type, and others. Most of these can be left at their default settings, unless specific adjustments are needed for the design.

3. **Placing Components**

Based on the requirements of the circuit, components are selected from the part library. Users should rotate and position the components on the schematic, assign part numbers, and package them according to the design specifications.

4. **Wiring the Schematic**

Utilize the various tools in Protel 99/Schematic to connect components with wires and electrical symbols, ensuring the schematic is electrically correct and complete.

5. **Adjusting the Circuit**

After the initial layout, the schematic should be adjusted and refined for clarity and accuracy, ensuring the diagram looks neat and all connections are correct.

6. **Generating Reports**

Various reports can be generated using Protel 99/Schematic’s report tools. The most important of these is the netlist, which is essential for the subsequent PCB design phase.

7. **File Saving and Printing Output**

The final step is to save the schematic file and print it out, ensuring all design details are properly documented for manufacturing.

**Design Principles for Microcontroller Control Boards:**

1. **Component Placement**

In PCB component layout, related components should be placed as close as possible. For example, clock generators, crystal oscillators, and CPU clock inputs tend to generate noise and should be placed near each other. Conversely, high-noise components, low-current circuits, and high-current switching circuits should be kept away from logic control circuits and memory components (e.g., ROM, RAM). If feasible, separate these circuits onto different boards to minimize interference and improve reliability.

2. **Decoupling Capacitors**

It is essential to install decoupling capacitors near key components such as ROM and RAM chips. PCB routing, pin connections, and other elements can introduce significant inductance, which can cause noise spikes on the VCC line. A 0.1µF decoupling capacitor between VCC and ground is a common solution to prevent these noise issues. When using surface-mount components, chip capacitors can be placed directly on the VCC pin for better performance. For high-frequency stability, ceramic capacitors are preferred over tantalum capacitors due to their lower impedance at high frequencies.

Key guidelines for decoupling capacitors include:

– Use a 100µF electrolytic capacitor at the power input for bulk decoupling, and consider larger capacitance if the design permits.

– Place a 0.01µF ceramic capacitor close to each IC. If space is tight, use 1~10µF tantalum capacitors around every 10 ICs.

– For components with weak interference immunity, such as RAM and ROM, place decoupling capacitors between the power (VCC) and ground lines. Minimize the lead length, especially for high-frequency bypass capacitors, to avoid charge accumulation.

3. **Grounding Design**

Proper grounding is crucial for reducing interference in microcontroller-based systems. Different types of ground wires—system, shielding, logic, and analog—should be carefully planned to ensure good circuit performance. Consider the following:

– Separate logic and analog grounds, each connected to their respective power grounds.

– Design the analog ground as thick as possible and increase the grounding area at the component leads.

– For analog signals, isolate the microcontroller circuitry using optocouplers to minimize noise interference.

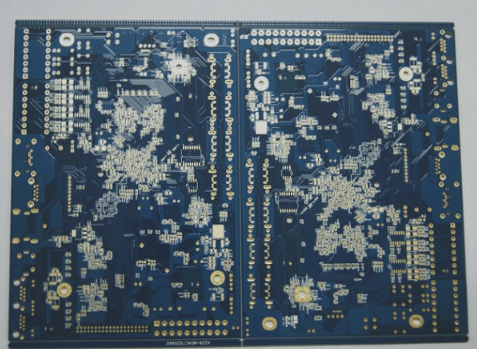

When routing the ground wire for logic circuits, aim to create a closed-loop structure to improve noise immunity. Ground wires should be as thick as possible. Thin ground traces increase resistance, causing voltage fluctuations and reducing the circuit’s anti-interference ability.

Grounding guidelines:

– When space allows, make the main ground trace at least 2~3mm wide, with component pin grounds around 1.5mm.

– For low-frequency signals (under 1MHz), a single-point ground may suffice to prevent interference.

– For higher frequencies (above 10MHz), use multi-point grounding to minimize impedance due to inductance effects.

Power lines should also be as wide as possible to reduce resistance and noise. Additionally, avoid routing signal traces through vias excessively, as these introduce capacitance that could affect high-frequency circuits. Keep the number of vias to a minimum to preserve the mechanical integrity of the PCB.

**Data Line Width**

To reduce impedance, the data line width should not be less than 0.3mm (12mil), with 0.46~0.5mm (18mil~20mil) being ideal. Excessive vias and holes should be avoided to minimize interference and maintain the structural strength of the PCB.