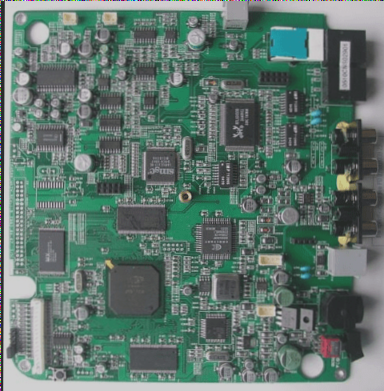

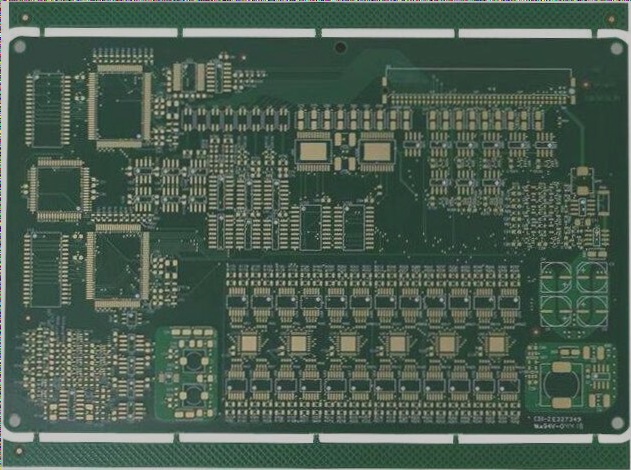

PCB Design Checklist for Electronic Engineers

- 1) Analyze the circuit to ensure smooth signal flow

- 2) Use short or isolated signal paths when necessary

- 3) Shield critical areas effectively

- 4) Utilize basic grid graphics

- 5) Optimize the PCB size

- 6) Maximize trace widths and spacing

- 7) Use preferred pad and hole sizes

- 8) Prepare PCB artwork and silkscreen appropriately

- 9) Minimize jumpers and avoid passing through components

Additional Inspection Items:

- 10) Ensure visibility and correctness of letters after assembly

- 11) Prevent copper foil blistering with appropriate windows

- 12) Include tool positioning holes

Electrical Characteristics Inspection:

- 1) Analyze wire resistance, inductance, and capacitance influences

- 2) Check wire accessory spacing for insulation requirements

- 3) Control insulation resistance in key areas

- 4) Fully identify polarity

- 5) Measure wire spacing impact on leakage resistance and voltage

- 6) Identify surface coating medium changes

Physical Characteristics Inspection:

- 1) Ensure pads and positions are suitable for assembly

- 2) Verify PCB can withstand shock and vibration

- 3) Determine spacing for standard components

- 4) Securely fix loose or heavy components

- 5) Correct heat dissipation and isolation

- 6) Position multi-lead components accurately

- 7) Eliminate potential interferences

- 8) Verify component arrangement and orientation

- 9) Check positioning hole sizes

- 10) Ensure comprehensive tolerances

- 11) Control physical properties of coatings

- 12) Maintain acceptable hole-to-lead wire ratios

Mechanical Design Factors:

PCBs provide mechanical support but should not be structural parts. Support every 5 inches on the PCB edge is recommended.

Installation Requirements:

Support should extend at least 1 inch from all edges. For different thicknesses, adjust support point distances for rigidity and resonance prevention.

Mounting Technologies Considerations:

- 1) PCB size and shape

- 2) Input and output terminals

- 3) Available equipment space

- 4) Loading and unloading ease

- 5) Attachment types

- 6) Heat dissipation needs

- 7) Shieldability requirements

- 8) Circuit interactions

Mounting Frames Requirements:

- 1) Ensure no component obstruction

- 2) Consider installation distances between PCBs

- 3) Design with appropriate mounting holes and slots

- 4) Account for plug-in tool sizes

PCB Assembly Tips for Plug-in Devices

- Attach plug-in devices securely to the PCB assembly using rivets.

- Design mounting frames with load-bearing flanges for PCBs.

- Ensure compatibility between plug-in tools and PCB size, shape, and thickness.

- Consider costs associated with plug-in tool usage, including tool price and additional expenses.

- Ensure sufficient equipment access for plug-in tool fastening and use.

When working on PCB assembly, it is crucial to follow these guidelines to ensure proper functioning and longevity of your electronic devices. By securely attaching plug-in devices and designing suitable mounting frames, you can enhance the performance and durability of your PCBs. Additionally, considering compatibility and costs associated with plug-in tools will help you make informed decisions during the assembly process. Remember to prioritize equipment access for efficient fastening and use of plug-in tools.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย