The Importance of AOI Technology in PCB Manufacturing

Automatic Optical Inspection (AOI) is a cutting-edge technology that utilizes optical principles to identify common defects in soldering production processes. In recent years, AOI has gained significant traction and is now widely adopted by manufacturers across various industries.

Key Applications of AOI Technology

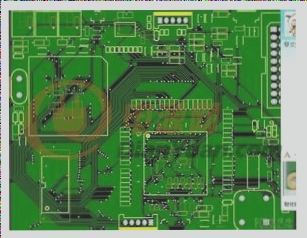

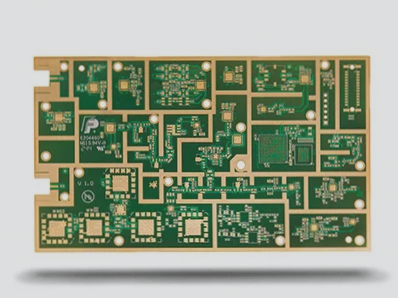

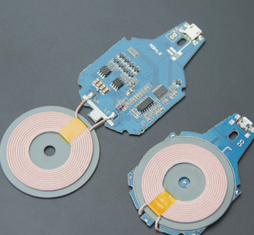

- PCB (Printed Circuit Board) fabrication

- Flat Panel Display (FPD) production

- Semiconductor manufacturing

- Photovoltaic industry

- Automotive electronics sector

During the automated inspection process, AOI systems scan PCBs using cameras, capture images, and compare solder joints with predefined parameters stored in a database. Defects are identified through image processing and highlighted for repair by technicians.

The Advancements in High-Performance AOI Systems

High-end AOI systems excel in providing top-notch image quality, speed, and stability for camera capture, setting them apart from standard AOI solutions.

Market Insights and Industry Trends

According to IHS data, China’s AOI market reached 7.62 billion yuan in 2015, with the PCB sector comprising a significant portion. The increasing demand for AOI equipment in the PCB/FPC industry stems from technical advancements, cost considerations, and evolving customer requirements.

Driving Factors for AOI Adoption

- Technological advancements have made manual visual inspections insufficient, necessitating machine-based inspections.

- As production costs rise and product prices fall, manufacturers must optimize processes and integrate automated testing equipment to stay competitive.

- Customer expectations for product reliability drive the need for AOI systems to detect defects effectively, enhancing overall quality and customer satisfaction.

As electronic components shrink in size, from 0402 to the minuscule 01005, the challenges in detection and maintenance increase. AOI equipment plays a vital role in early defect detection, ensuring product quality, efficiency, and minimizing losses in production.