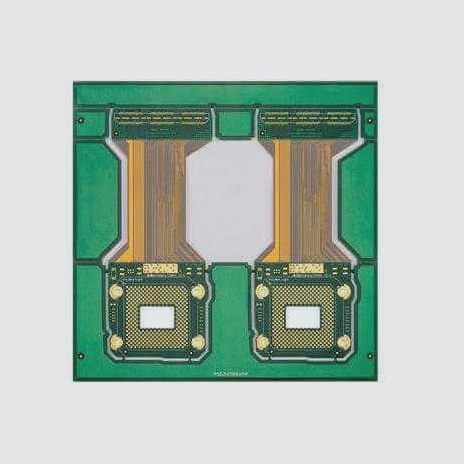

PCB Plating Processes: Gold Plating and Tin Plating

PCBA plate making is crucial, with gold plating and tin plating processes playing significant roles in PCB manufacturing.

Advantages and Disadvantages of Different PCB Coatings

- Zinc Plating: Offers corrosion prevention at a low cost but may not be suitable for frictional parts.

- Nickel Plating: Provides excellent chemical stability but suffers from porosity.

- Tin Plating: Ensures high chemical stability and good solderability.

- Chrome Plating: Comes in decorative and hard variants, each with specific benefits.

- Gold and Silver Plating: Primarily used for decoration and corrosion resistance, but can be costly.

Benefits of Gold-Plated PCBs

Gold-plated PCBs offer several advantages:

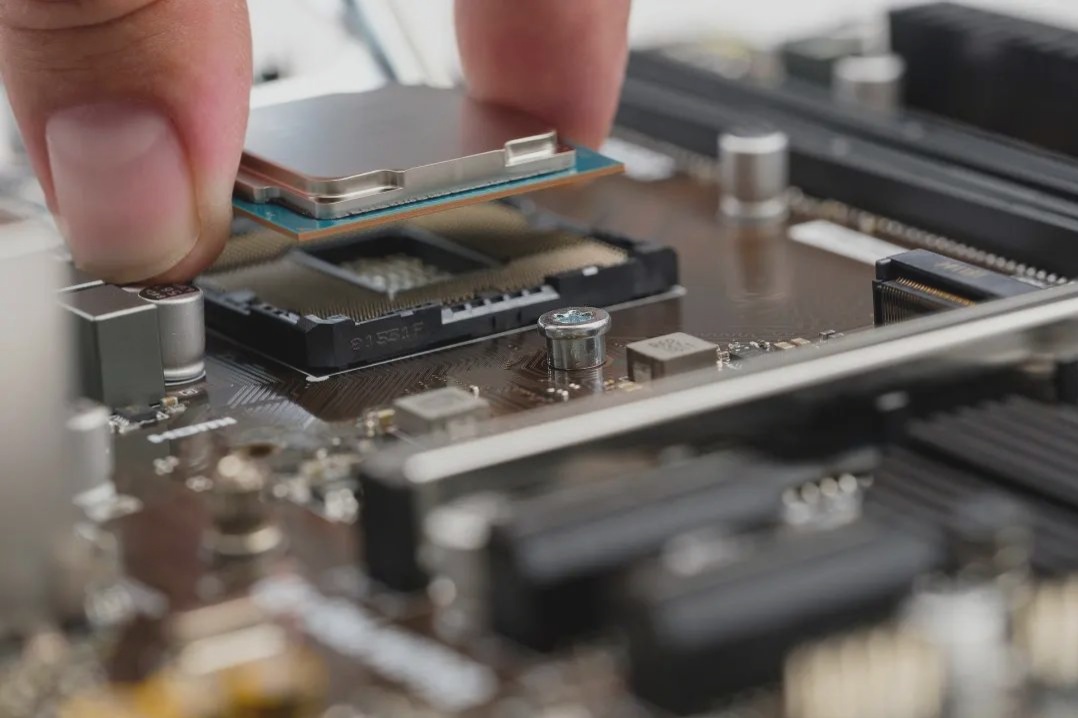

- Improved IC pin density and SMT placement.

- Extended shelf life for sample stage production.

Advantages of Heavy Gold Plating

- Immersion gold technology reduces the tin effect for better compatibility.

- Enhanced soldering capabilities and customer satisfaction.

- Prevention of signal interference and short circuits.

- Stronger adhesion between layers for improved performance.

- Easier stress management and comparable flatness to gold-plated boards.