Understanding Impedance in PCBs

Characteristics and Importance

- Resistance is a common characteristic of PCBs.

- Consistent transmission line conditions indicate high quality.

- Controlled impedance circuit boards have uniform impedance across all transmission lines, usually between 25 and 70 ohms.

- Instability in performance over time can lead to impedance variations in PCBs.

- Lower impedance values indicate better performance.

Factors Affecting Impedance

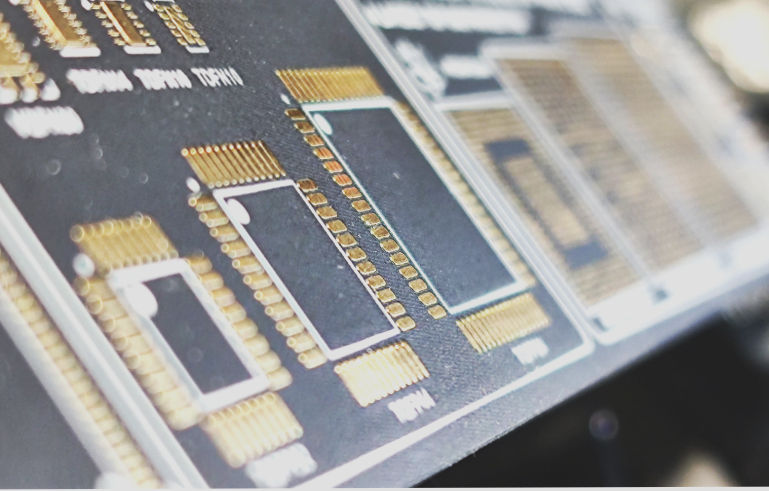

- PCBs undergo copper electroplating with tin to maintain resistivity and ensure low overall impedance.

- Improper impedance standards can lead to circuit board malfunction.

Tin Plating Process

Electroless tin plating technology is crucial in the electronics industry, affecting impedance significantly. Companies have varying expertise in chemical tin plating, with limited execution in China.

The susceptibility of the electroless tin layer to discoloration can lead to poor electrical conductivity.

Thorough research and testing confirm Tongqian’s electroless tin layer as pure tin with low resistance, ensuring high-quality conduction and soldering.

Subpar imitation of tin plating can result in impedance issues, affecting electronic devices’ performance.

The purity and resistance of the tin coating are essential for connecting electronic components to the copper foil in PCBs, impacting overall performance.

Factors Affecting Signal Transmission in PCBs

- Compounds in Tin Plating Layer: Besides pure metals, compounds in tin plating can impact conductivity and resistivity levels, affecting signal transmission in digital circuits.

- Characteristic Impedance: Inconsistent impedance can hinder circuit board and machine performance.

- Coating Material Influence: Coating material and performance at the PCB base directly affect characteristic impedance.

- Challenges in Impedance Management: Aging coatings and environmental factors can subtly alter impedance, making it challenging to detect and address.

Effective management of impedance in PCBs requires a deep understanding of the root causes and proactive measures to tackle coating issues.