The Importance of Components in PCB Circuit Board Production

When it comes to PCB circuit board production, sourcing components from professional shops can provide valuable insights and assistance from knowledgeable professionals. These shops offer a wide range of electronic processing equipment and tools essential for creating circuit boards.

Choosing the Right Components

Specialized shops not only provide components but also offer tools like soldering irons, soldering tin, and power tools necessary for PCB fabrication. It’s essential to select the right components, such as connecting wires of various colors, which can be more cost-effective when purchased from these specialty stores.

The Role of Resistors

Resistors are crucial components in PCB circuit board production, serving purposes like current limiting, voltage division, and heat generation. Understanding resistance is key, as it determines how much a conductor hinders current flow. It’s important to match resistor specifications with circuit requirements to ensure optimal performance.

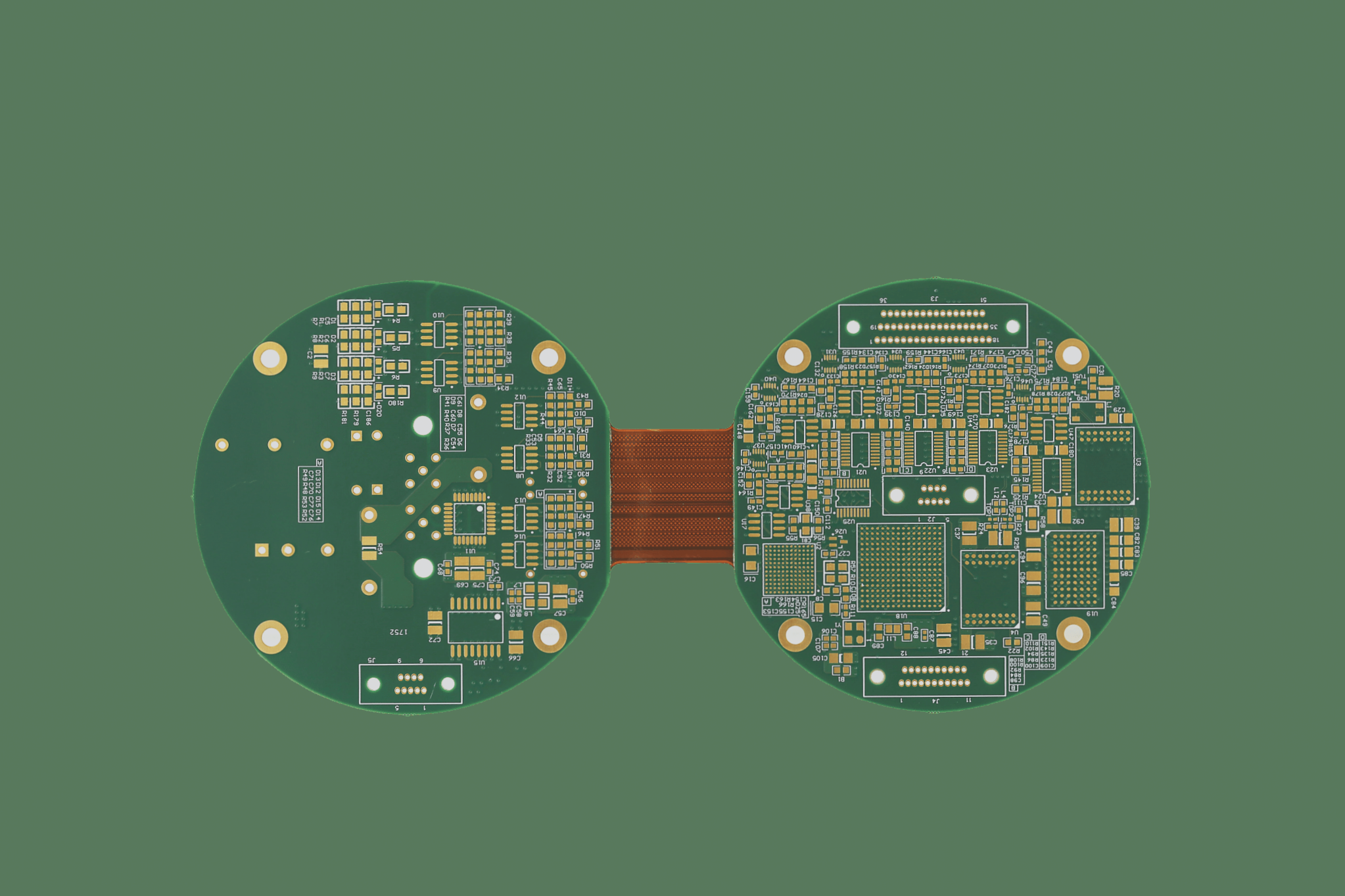

WellCircuits Limited: Your PCB Manufacturing Partner

WellCircuits Limited specializes in high-precision circuit boards, offering double-sided, multi-layer, and impedance-controlled boards. Their product range includes HDI, thick copper boards, rigid-flex combinations, and more, catering to diverse customer needs for various products.

- Double-sided, multi-layer, and impedance-controlled circuit boards

- Specialized in HDI and thick copper boards

- Offers rigid-flex combinations and buried capacitance/resistance boards

Whether you are a beginner or an experienced professional, having access to quality components and reliable manufacturers like WellCircuits Limited is essential for successful PCB circuit board production.