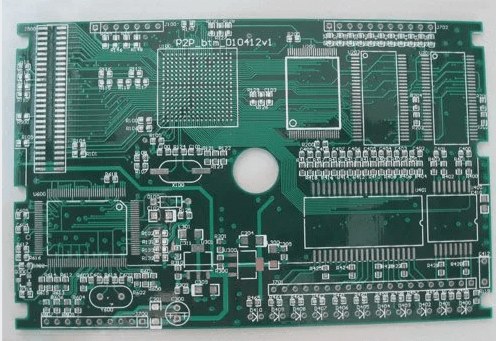

Preventing Electrostatic Discharge (ESD) and Electrical Overload (EOS) Risks in PCBAs

Electrostatic discharge (ESD) poses a significant threat to printed circuit board assemblies (PCBAs) due to its potential to damage sensitive components. These components, known as Electrostatic Discharge-Sensitive (ESDS) components, are vulnerable to even minimal levels of electrostatic energy. The resulting current from ESD can lead to electrical overstress (EOS) or complete component failure.

- Proper prevention and protection measures are crucial in safeguarding PCBAs from ESD and EOS damage.

- Effective circuit protection mechanisms must be integrated into the PCBA design and assembly process to mitigate risks.

- Identification and marking of ESD-sensitive components are essential, along with the implementation of anti-static handling protocols.

Managing ESD and EOS Risks

Minimizing the impact of ESD and EOS on PCBA components requires a comprehensive approach:

- Thoroughly inspect components for potential electrostatic spikes, ensuring a safe operating voltage level.

- Exercise caution when handling sensitive components to prevent accidental damage.

- Avoid generating voltage spikes above 0.3V from soldering irons, test equipment, and other tools in contact with components.

Understanding EOS and ESD Hazards

Distinguishing between EOS and ESD damage is crucial in diagnosing issues affecting PCBA components:

- Confirm whether EOS or ESD is the primary cause of component damage to implement appropriate mitigation strategies.

- Improper handling and workplace negligence are common sources of EOS/ESD damage.

Sources of Electrostatic Charges

Electrostatic charges can arise from everyday activities and materials:

- Be mindful of activities that can generate static charges, such as handling non-conductive materials or using plastic-based tools.

- Even air molecules colliding in specific conditions can lead to electrostatic discharges.

The Dangers of Electrostatic Discharge (ESD) on PCB Components

Electrostatic discharges pose a significant threat to the components on a Printed Circuit Board (PCB), especially when the static charge is near a conductive surface like human skin. The discharge spark can jump between conductors, causing irreversible harm to delicate parts on the PCBA.

Impact of ESD on ESDS Components

When someone with an electrostatic potential touches a PCB, an electrostatic discharge occurs. This discharge can travel through the PCB’s conductive paths, reaching components that are highly sensitive to ESD. Even if the discharge is too weak to be felt (typically below 3500V), it can still cause significant harm to ESDS components, potentially resulting in failure or reduced performance.

Significance of Understanding Component Sensitivity

PCB manufacturers and assembly teams must grasp the sensitivity levels of the components they work with, especially those prone to EOS/ESD damage. This understanding is crucial for preventing harm during manufacturing, handling, and testing phases.

Implementing preventive measures and adhering to strict handling protocols can reduce the risk of EOS/ESD damage, safeguarding the reliability and durability of the PCBA.

If you have any inquiries regarding PCB or PCBA, don’t hesitate to contact me at info@wellcircuits.com.