The Role of Dispensing Machines in Surface Mount Technology (SMT) Manufacturing

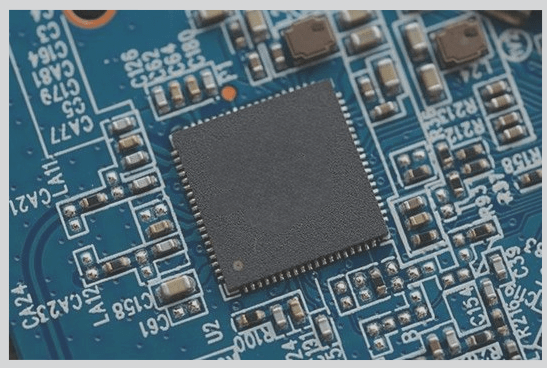

In the realm of SMT manufacturing, dispensing machines are crucial for applying adhesives, solder paste, and other materials onto PCBs with precision. This ensures secure connections and optimal device performance. Let’s delve into the importance, types, working principles, advantages, applications, and future developments of these machines.

Types of Dispensing Machines

- Jet Dispensers: Offer fast, high-precision dispensing without direct contact with the PCB, ideal for speed and fine accuracy.

- Pin Dispensers: Provide a traditional, mechanical method suitable for larger material quantities.

- Needle Dispensers: Versatile machines that handle various materials with great precision, perfect for high-precision applications.

Working Principles

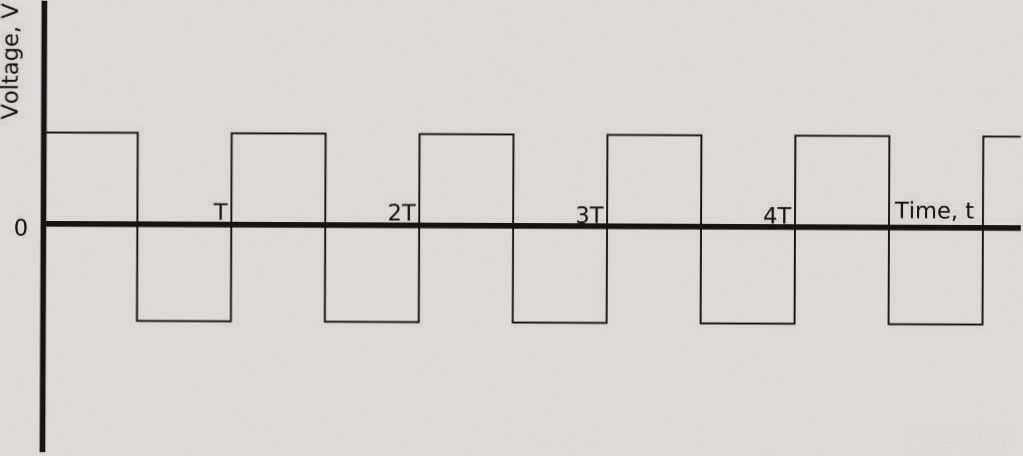

The working principle involves material feeding, precise control, and deposition onto the PCB. Modern machines use advanced control systems, sensors, and cameras to regulate material flow, ensuring uniform distribution and reducing human error for consistent results.

Advantages of Dispensing Machines

- Ensure accuracy and consistency, reducing defects and improving production yield.

- Enhance efficiency by speeding up material application, crucial for high-volume manufacturing.

- Minimize material waste, leading to cost savings and sustainability.

- Reduce manual interventions, streamlining the assembly line.

Applications and Future Developments

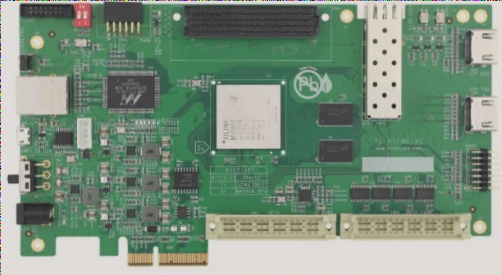

Dispensing machines are used in various SMT processes like solder paste application, adhesive dispensing, and underfill materials for component protection. They are essential for complex PCB assembly in industries such as smartphones, automotive electronics, and medical devices. The future holds promising advancements with intelligent and adaptable machines using automation, AI, machine learning algorithms, and eco-friendly materials for enhanced precision and sustainability.

Conclusion

Dispensing machines are essential in modern SMT manufacturing, providing precision, efficiency, and cost-effectiveness. They play a vital role in ensuring high-quality connections and reliable assembly, especially in industries where performance and durability are critical. As technology advances, dispensing machines will become more sophisticated, aiding in the production of complex and dependable electronic devices. Manufacturers investing in cutting-edge dispensing technologies will be better positioned to meet the increasing demands for miniaturization, speed, and sustainability in the electronics industry.

Types of Dispensing Machines

- Manual Dispensing Machines: Ideal for small-scale production or prototyping, operated by hand with flexibility for diverse applications. Requires skilled operators and is more time-consuming than automated systems.

- Semi-Automatic Dispensing Machines: Balancing manual and automated features, reducing labor intensity and human error. Suitable for mid-volume production requiring speed and flexibility.

- Fully Automatic Dispensing Machines: Designed for high-volume production with precision and speed, minimizing human error and maximizing throughput by dispensing materials based on predefined patterns.

Working Principle of Dispensing Machines

- Material Preparation: Loading materials like adhesives or solder paste into the dispensing head, ensuring proper consistency and flow properties through heating or mixing.

- Motion Control: Computer-guided motion system directing the dispensing head along a specified path on the PCB for accurate positioning and timing.

- Dispensing Process: Releasing material in dots or lines as per PCB design, with advanced machines adjusting speed, volume, and pattern dynamically for improved accuracy.

Advantages of Dispensing Machines

- Increased Efficiency: Speeding up material application for higher production output and reduced cycle times compared to manual methods.

- Improved Quality: Minimizing defects like insufficient soldering, ensuring consistent and reliable products with precise material control.

- Cost Reduction: Minimizing waste and labor needs, optimizing raw material use for long-term operational savings.

Utilization of Dispensing Machines

Dispensing machines find wide applications in various sectors of the electronics industry, particularly in PCB assembly where they are crucial for applying solder paste on PCBs to facilitate component placement during assembly.

Applications of Dispensing Machines in Various Industries

- PCB Assembly: Dispensing machines are crucial for precise application of materials in PCB assembly, ensuring high quality and reliability of electronic components.

- Optoelectronic Products: In LED lighting and displays, dispensing machines play a vital role in encapsulation and bonding processes, guaranteeing durability and optimal performance.

- Automotive Electronics: Essential for assembling automotive control systems and sensors, dispensing machines provide the precision and durability required in the automotive industry.

- Medical Devices: Dispensing machines in the medical sector ensure accurate connections between electronic components in diagnostic equipment, monitoring systems, and implants.

Technological Advancements and Trends

- Advancements in Technology: Emerging techniques like laser dispensing and 3D printing are enhancing the precision and complexity of dispensing processes.

- Miniaturization and Flexibility: The trend towards smaller electronic devices is driving the need for more compact and adaptable dispensing solutions.

- Smart Technology and Automation: Integration of smart technologies and automation is improving the efficiency and adaptability of dispensing machines, meeting market demands effectively.

Future Outlook

As technology continues to advance, dispensing machines will evolve to meet the demands of modern manufacturing. With ongoing innovations, these machines will play a pivotal role in ensuring the reliability, precision, and efficiency of electronic assembly processes.