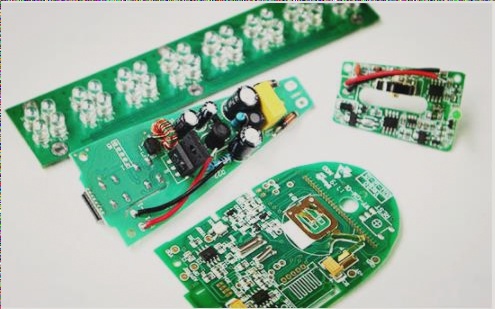

2. First, the antenna elements of 5G base stations require PCBs for connectivity.

3. Secondly, there will be a substantial increase in the number of filters and other components within 5G base stations, necessitating a dedicated PCB to connect these elements.

4. Finally, components such as CU/DU in 5G base stations will also rely on PCB technology.

5. These developments are poised to significantly elevate PCB usage.

6. By taking into account both the quantity of base stations and the value of each, we can estimate the expansive market potential that 5G base stations present for PCBs.

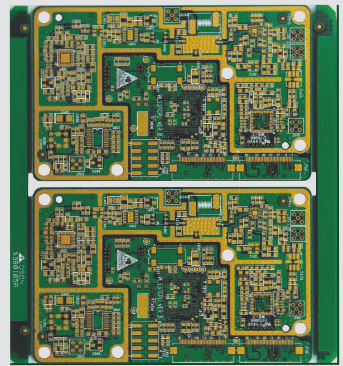

7. As a key player in industrial laser equipment, the laser coding machine has been instrumental in advancing the PCB industry.

8. By integrating laser marking technology with computer systems, the laser coding machine utilizes current software control to effectively mark two-dimensional codes, characters, product numbers, barcodes, and serial numbers on both metal and non-metal materials.

Production dates, patterns, logos, and various special symbols can also be customized and personalized. Enhanced product quality control allows for comprehensive tracking of production information throughout the entire process, ensuring quality management of electronic products. This leads to increased productivity, reduced costs, minimized pollution, and adaptability to multi-variety, small-batch production, with permanent marking and traceability during manufacturing.

Beyond Laser’s CY-CBLF-7070 large-format automatic laser coding machine is primarily utilized in PCB, FPCB, SMT, and other sectors. It automatically marks two-dimensional codes on the surface of PCB/FPCB (select the appropriate model based on different formats). This machine can also mark one-dimensional codes and characters on various inks, including white oil, green oil, and black oil, as well as on surfaces such as copper, stainless steel, and aluminum alloy.

The structure of the PCB large-format automatic laser coding machine includes a machine table, an operation panel, a feeding mechanism, a receiving mechanism, a vacuum adsorption platform, a feeding movement module, a discharging movement module, and a laser optical system. Loading and unloading trolleys and vacuum adsorption robots facilitate automatic material handling. The XY precision mobile platform, CCD vision positioning, laser automatic coding, and CCD vision code reading self-check function seamlessly integrate into a precise control system, enhancing overall automation.

Application characteristics of the CY-CBLF-7070 PCB large-format automatic laser coding machine include:

1. Imported CO2, fiber optic, green light, and ultraviolet lasers, ensuring stable performance;

2. High-speed imported galvanometers that deliver precise processing and rapid marking, with consistent performance;

3. A user-friendly software interface that is easy to operate and features robust editing capabilities;

4. No consumables needed compared to traditional printing methods, making it environmentally friendly, pollution-free, and maintenance-free;

5. The capability to automatically read QR codes, save data, and provide alerts for unreadable codes;

6. Customization options for automatic loading and receiving machines;

7. The ability to automatically retrieve work order numbers, product batch numbers, material codes, and product specifications for seamless coding.

As the commercialization of 5G generates hundreds of billions in output value, it imposes higher demands on the R&D, production, and management capabilities of PCB companies. Beyond Laser, a leading laser equipment manufacturer, is committed to delivering more cost-effective products to the market. We aim to assist companies in enhancing product management traceability, seizing 5G opportunities, and embracing a new stage of development.