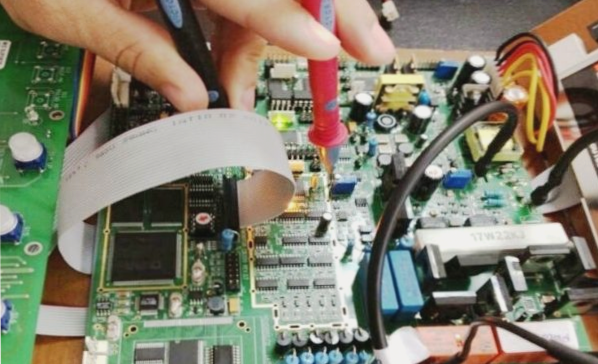

The Importance of PCB Stackup in Electronics Manufacturing

Enhancing Performance and Reliability

- PCB stackup is crucial for signal integrity in electronic devices.

- Optimizing layer arrangement improves performance in high-speed circuits.

- Proper stackup design reduces signal degradation and enhances device reliability.

Thermal Management for Efficient Heat Dissipation

Effective heat dissipation is essential for maintaining performance and component lifespan. Incorporating thermal layers and materials with high thermal conductivity ensures even heat distribution, especially in high-power applications.

Reducing Electromagnetic Interference (EMI)

Shielding techniques in PCB stackup, such as ground planes, help reduce EMI and isolate sensitive signal traces. Proper grounding minimizes interference, crucial for telecommunications and high-frequency circuits.

Ensuring Mechanical Integrity

A robust PCB stackup enhances the board’s ability to withstand mechanical stress, improving resistance to warping and cracking. Selecting appropriate materials and optimizing layer arrangement are vital for long-term functionality, particularly in portable devices.

Optimizing Manufacturing Efficiency and Cost

Designing a well-planned stackup streamlines manufacturing, making the process more efficient and cost-effective. Aligning stackup design with manufacturer capabilities minimizes delays and reduces costs, meeting technical and budgetary requirements.

Optimizing PCB Stackup for Performance and Reliability

An optimized PCB stackup is crucial for balancing thermal management, EMI shielding, mechanical reliability, and manufacturing efficiency. These factors are key to ensuring the performance, durability, and cost-effectiveness of electronic devices in today’s demanding applications.

Factors to Consider in PCB Stackup Design:

- Cost Consideration: Cost plays a critical role in production environments. Designers need to strike a balance between performance and cost-efficiency by carefully selecting the number of layers and materials to meet requirements without exceeding budget constraints.

- Reliability Importance: A well-structured stackup is essential for long-term reliability, enhancing resistance to environmental factors like humidity and mechanical stress. This is crucial for applications where failure can have severe consequences, such as in medical or aerospace systems.

Key Insights:

The PCB stackup directly impacts signal integrity, thermal management, mechanical strength, and cost control, influencing the final product’s performance and reliability. As technology advances, optimizing the stackup remains vital for creating high-performance electronic devices.

Conclusion:

A successful PCB design requires balancing performance, cost, and reliability. By choosing the right stackup to meet technical specifications while considering material costs and environmental stresses, designers can create PCBs that deliver optimal performance and long-term durability.

Summary:

The PCB stackup is fundamental in electronic design, impacting critical factors like signal integrity and thermal management. Optimizing the stackup is essential for creating reliable and cost-effective products that meet the evolving demands of modern technology.