The Evolution of PCB Assembly: Robotics, Automation, and Quality Control

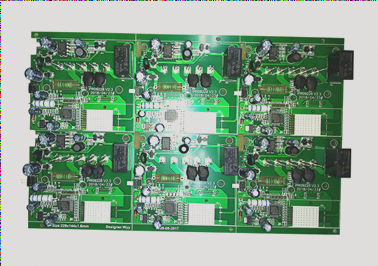

In today’s fast-paced electronics industry, the need for efficient and cost-effective production processes is greater than ever. Printed Circuit Board Assembly (PCBA) is crucial in manufacturing electronic devices, requiring precision, scalability, and reliability. Automation and robotics have revolutionized PCBA production, enhancing efficiency and product quality.

Role of Robotics in PCBA

- Robots improve precision and reduce human error in tasks like component placement, soldering, inspection, and testing.

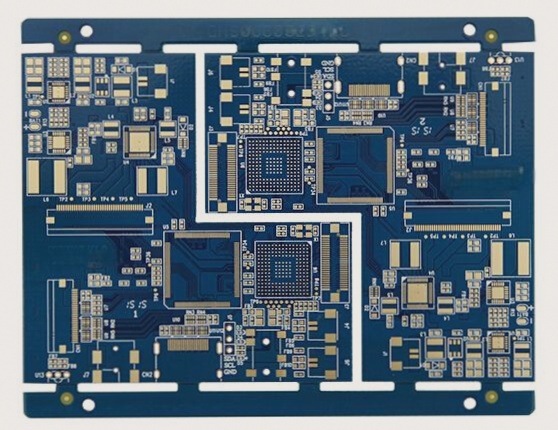

- Pick-and-place robots ensure high-speed and high-precision component placement on PCBs, speeding up production cycles and enabling assembly of complex circuit boards.

Advancements in Automated Assembly Lines

- Automated assembly lines integrate machines and robotic systems to streamline tasks like component feeding, soldering, and testing, increasing throughput and reducing labor costs.

- Reduced human intervention minimizes errors and ensures consistent production standards.

Importance of Intelligent Monitoring Systems

- Intelligent monitoring systems utilize sensors, cameras, and data analytics to provide real-time feedback on production stages, enabling early issue detection and process optimization.

- Precision monitoring prevents defects and ensures high-quality standards are met consistently.

Further Enhancements in PCBA Manufacturing

The integration of robotics, automated assembly lines, and intelligent monitoring systems has transformed PCBA manufacturing, improving efficiency, reducing errors, and enabling the assembly of precise circuit boards. As the demand for high-quality electronic devices grows, automation in PCBA will play a critical role in meeting industry challenges.

Recent Developments in PCBA Manufacturing:

- Automated soldering systems outperform manual methods in speed and precision, delivering consistent, high-quality solder joints crucial for industries like automotive, aerospace, and medical devices.

- Automated assembly lines have become essential in modern PCBA production, reducing operational costs, streamlining processes, and meeting increasing demand with efficiency.

Advantages of Automated Assembly Lines in PCBA Production

- Increased Throughput: Automated systems operate 24/7, boosting production capacity and reducing time-to-market pressure.

- Enhanced Consistency and Quality: Machines eliminate human error, ensuring precise execution and uniformity in PCBAs.

Integration of Robots and Automation

The use of robots and automation in soldering and assembly processes has transformed PCBA production. These systems improve efficiency, cut costs, and maintain high-quality standards crucial for reliability and safety.

Key Aspects of Automation in Assembly Lines

- Scalability: Automated systems easily adjust to fluctuating demands, minimizing downtime and reconfiguration needs.

- Intelligent Monitoring Systems: Incorporating sensors and advanced software for real-time tracking, analysis, and defect detection.

Benefits of Intelligent Monitoring

- Real-time Defect Detection: AOI and X-ray inspection technologies identify issues like misaligned components or defective solder joints.

- Predictive Maintenance: Data-driven systems predict equipment failures, enabling proactive maintenance and reducing downtime and repair costs.

Data Analytics Optimization

Analyzing production line data helps identify inefficiencies, optimize resources, and meet production targets consistently.

Revolutionizing PCBA Production

The integration of robotics, automation, and intelligent monitoring systems is reshaping the electronics manufacturing industry. These technologies enhance precision, speed, and scalability, meeting the demand for high-quality electronic products efficiently.

Transforming PCBA Production with Automation and Intelligent Monitoring Systems

Staying competitive in the rapidly evolving electronics industry requires companies to embrace automation and intelligent monitoring systems. These advanced solutions are no longer optional but essential for success. By implementing cutting-edge technologies, manufacturers can streamline processes, drive innovation, and ensure long-term growth and resilience.

Key Benefits of Integration:

- Enhanced efficiency

- Improved precision

- Increased scalability

The integration of data analytics, robotics, and intelligent systems is revolutionizing PCBA production. As the demand for complex electronics continues to rise, these technologies play a crucial role in maintaining competitiveness and fostering innovation. Companies that adopt these solutions will gain a strategic advantage in a dynamic market, positioning themselves for sustained success.