The Power of Online PCB Testers

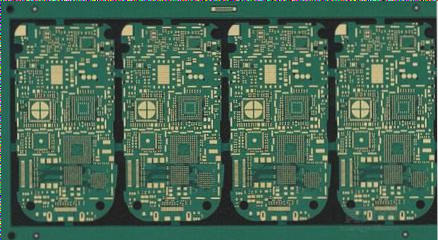

Online testers are essential tools for testing and repairing PCBA boards. They can conduct functional tests on various integrated circuits and measure V-I curves on PCBs. Let’s explore the main functions of these testers:

1. Functional Test

The functional test, known as ICFT, activates circuits using the post-drive principle to analyze and derive results. By adjusting input levels, the tester isolates the gate under test to verify logical relationships, ensuring proper circuit functionality.

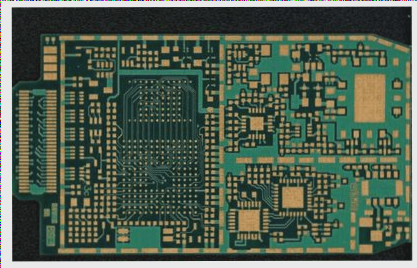

2. Curve Test

Curve testing, specifically the VI curve test, helps identify faults by comparing curve forms. By testing nodes on both functioning and faulty PCBs, the tester can pinpoint fault points for efficient repairs.

3. Memory Test

For RAM, the write/read method is used to detect faults. ROM is tested by comparing stored content with expected data. These tests ensure memory components are functioning correctly.

4. Status Test

Checking the logic level of each pin on a device helps determine functionality by comparing it with a known good device.

5. Custom Test

Users can define input pin excitation and logical relationships for digital circuit tests. If the defined relationships are met, the device is deemed functional.

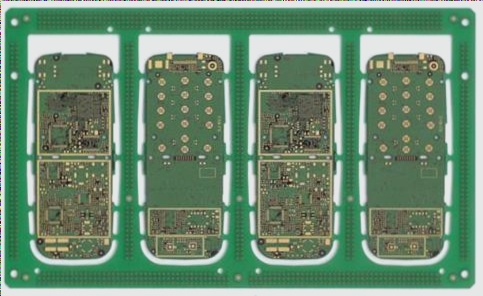

Utilizing Online Testers in PCB Repair

1. Preparation Before Maintenance

Create diagrams and comparison libraries to aid in diagnosing faulty PCBs. These resources provide crucial references during the repair process.

2. Repair Steps

- Visual Inspection: Gather information and inspect the board for visible issues.

- Power Supply Testing: Use a multimeter to check for short circuits.

- Offline Testing: Remove components for isolated testing.

- Online Testing: Identify failure points on the board.

- Trial Run: Verify repairs with online tests.

- Record Keeping: Document findings and observations for future reference.

If you require PCB manufacturing services, feel free to contact us. We’re here to help!