PCBA Process for Different Types of PCB Boards

-

Single-sided SMT Mounting

Involves applying solder paste to component pads, placing electronic components, and reflow soldering.

-

Single-sided DIP Cartridge

For PCBs with through-hole components, components are inserted before wave soldering.

-

Single-sided Mixed

Combines solder paste printing, reflow soldering, DIP insertion, and either wave or manual soldering.

-

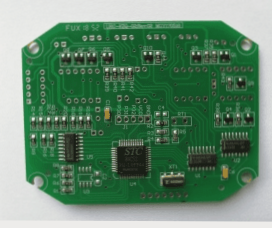

Single-sided Mounting and Plug-in Mixing

Double-sided PCBs with one side mounted and the other using inserted components.

-

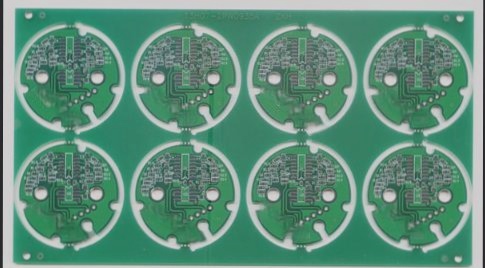

Double-sided SMT Mounting

Enhances aesthetics and functionality by mounting components on both sides.

-

Double-sided Mixed

Two methods for double-sided assembly, optimizing efficiency and soldering processes.

Considerations for PCBA Assembly

The solder paste printing process focuses on achieving consistent volume distribution for each solder joint, influenced by area ratio and transfer rate.

-

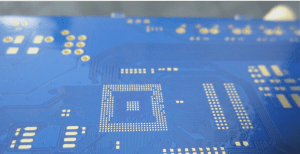

Area Ratio

Proportion of stencil window area to window hole wall area.

-

Transfer Rate

Ratio of actual solder paste transferred to the volume of the stencil window.

-

Effect of Area Ratio on Transfer Rate

Area ratio impacts solder paste transfer efficiency, with an engineering requirement of over 0.66 for optimal rates.

-

Design Requirements for Area Comparison

Steel mesh design considerations for maintaining area ratio, especially for fine-pitch components.

If you have any PCB manufacturing needs, feel free to contact us.