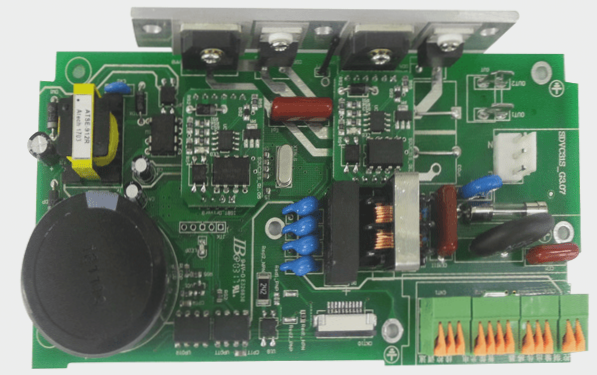

Benefits of Copper Plating in PCBs

There are numerous advantages to utilizing copper plating in printed circuit boards (PCBs). One key benefit is the reduction of ground wire impedance, which plays a crucial role in minimizing interference within digital circuits. By lowering the impedance of the ground wire, the impact of spike currents in digital circuits can be effectively mitigated.

Moreover, copper plating serves the significant purpose of enhancing the overall performance of the circuit. It not only contributes to a more aesthetically pleasing appearance but also aids in noise suppression and the reduction of high-frequency interference.

Copper-Clad Block vs. Grid

When comparing a copper-clad block to a grid layout on a PCB, several functions come into play. The grid design offers benefits such as improved aesthetics, noise reduction, and the ability to minimize high-frequency interference. However, it is essential to consider wiring guidelines that emphasize the importance of wide power supply and ground layers.

While grids may seem counterintuitive from a high-frequency perspective due to the risk of sharp traces, their implementation is often a result of manufacturing requirements. For instance, wave soldering processes necessitate specific board designs to prevent tilting and ensure successful chip integration.

Notably, some surface mounts may not incorporate grids. This could indicate superior corrosion processes or the utilization of advanced reflow soldering techniques, albeit at a higher cost. Ultimately, the choice between grid and block designs depends on the specific needs of the PCB assembly process and the desired level of product consistency.