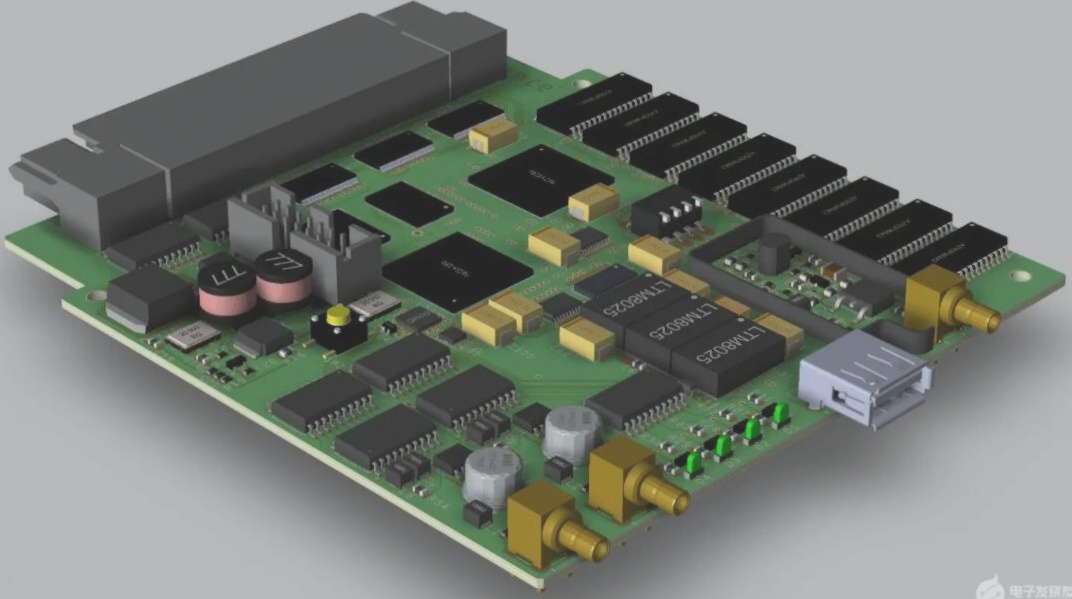

On the printed circuit board, copper is used to interconnect the components on the substrate. Although it is a good conductor material for forming the pattern of the conductive path of the printed circuit board, if it is exposed to the air for a long time, it is easy to lose its luster due to oxidation, and lose its weldability due to corrosion. Therefore, various technologies must be used to protect copper traces, vias, and plated through holes. These technologies include organic paint, oxide film, and electroplating.

Organic paint is very simple to use, but it is not suitable for long-term use due to changes in its concentration, composition, and curing cycle. It even leads to unpredictable deviations in weldability. Oxide film can protect the circuit from corrosion, but it cannot maintain solderability. Electroplating or metal coating processes are standard operations to ensure solderability and protect circuits from corrosion and play an essential role in the manufacture of single-sided, double-sided, and multilayer printed circuit boards. In particular, plating a layer of solderable metal on the printed wire has become a standard operation to provide a solderable layer for the copper printed wire.

The interconnection of various modules in electronic equipment often requires the use of a printed circuit board socket with spring contacts and a printed circuit board with connecting contacts designed to match it. These contacts should have a high degree of wear resistance and very low contact resistance, which requires a layer of rare metals to be plated on them. The most commonly used metal is gold. In addition, other coated metals can also be used on the printed lines, such as tin plating, plating, and sometimes copper plating in certain areas of the printed lines.

Another type of coating on the copper printed line is organic, usually a solder mask, where there is no need for soldering, screen printing technology is used to cover a layer of epoxy resin film. This process of applying a layer of organic solder preservative does not require electronic exchange. When the circuit board is immersed in the electroless plating solution, a nitrogen-resistant compound can stand on the exposed metal surface and will not be absorbed by the substrate.

The precise technology required by electronic products and the strict requirements of environmental and safety adaptability have promoted considerable progress in electroplating practice, which is clearly reflected in the manufacturing of high-complexity, high-resolution multi-substrate technology. In electroplating, through the development of automated, computer-controlled electroplating equipment, the development of high-complex instrument technology for chemical analysis of organics and metal additives, and the emergence of technologies for precise control of the chemical reaction process, electroplating technology has reached a very high level.

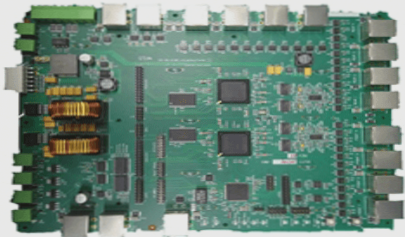

Organic paint is very simple to use, but it is not suitable for long-term use due to changes in its concentration, composition, and curing cycle. It even leads to unpredictable deviations in weldability. Oxide film can protect the circuit from corrosion, but it cannot maintain solderability. Electroplating or metal coating processes are standard operations to ensure solderability and protect circuits from corrosion and play an essential role in the manufacture of single-sided, double-sided, and multilayer printed circuit boards. In particular, plating a layer of solderable metal on the printed wire has become a standard operation to provide a solderable layer for the copper printed wire.

The interconnection of various modules in electronic equipment often requires the use of a printed circuit board socket with spring contacts and a printed circuit board with connecting contacts designed to match it. These contacts should have a high degree of wear resistance and very low contact resistance, which requires a layer of rare metals to be plated on them. The most commonly used metal is gold. In addition, other coated metals can also be used on the printed lines, such as tin plating, plating, and sometimes copper plating in certain areas of the printed lines.

Another type of coating on the copper printed line is organic, usually a solder mask, where there is no need for soldering, screen printing technology is used to cover a layer of epoxy resin film. This process of applying a layer of organic solder preservative does not require electronic exchange. When the circuit board is immersed in the electroless plating solution, a nitrogen-resistant compound can stand on the exposed metal surface and will not be absorbed by the substrate.

The precise technology required by electronic products and the strict requirements of environmental and safety adaptability have promoted considerable progress in electroplating practice, which is clearly reflected in the manufacturing of high-complexity, high-resolution multi-substrate technology. In electroplating, through the development of automated, computer-controlled electroplating equipment, the development of high-complex instrument technology for chemical analysis of organics and metal additives, and the emergence of technologies for precise control of the chemical reaction process, electroplating technology has reached a very high level.