The Importance of Copper Protection on Printed Circuit Boards

Copper is a crucial material used in printed circuit boards (PCBs) to interconnect components on the substrate. While copper is an excellent conductor for forming conductive paths, it is prone to oxidation and corrosion when exposed to air for extended periods. To protect copper traces, vias, and plated through holes, various technologies are employed.

- Organic Paint: Organic paint is a simple solution for protecting copper, but it may not be suitable for long-term use due to changes in concentration and composition, leading to unpredictable deviations in weldability.

- Oxide Film: An oxide film can prevent corrosion but may compromise solderability.

- Electroplating: Electroplating with solderable metals is a standard process to ensure solderability and protect circuits from corrosion, especially in the production of single-sided, double-sided, and multilayer PCBs.

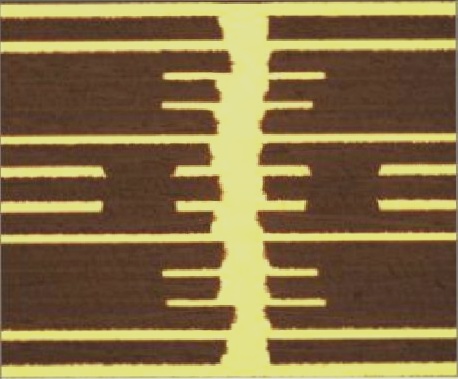

Enhancing Connectivity with Printed Circuit Board Sockets

Electronic equipment often requires printed circuit board sockets with spring contacts designed for optimal connectivity. These contacts must exhibit high wear resistance and low contact resistance, often achieved by plating rare metals like gold on them. Additionally, other metals such as tin and copper can be used for specific areas on printed lines.

Protecting Copper Printed Lines with Organic Coatings

Organic coatings, such as solder masks, are applied to copper printed lines where soldering is unnecessary. By using screen printing technology to cover the lines with an epoxy resin film, a layer of organic solder preservative is created without the need for electronic exchange.

Advancements in Electroplating Technology

The evolving demands of electronic products and the need for environmentally safe practices have driven significant advancements in electroplating technology. Automated equipment, precise chemical analysis tools, and technologies for controlling chemical reactions have elevated electroplating to new heights, especially in producing high-complexity PCBs with multi-substrate technology.