The Evolution of PCB Laminates in Modern Electronics

In today’s fast-paced world of high-performance electronic devices, the demand for cutting-edge PCB laminates is at an all-time high. These devices require laminates with top-notch electrical properties, improved mechanical stability, and exceptional performance to keep up with the complexities of modern applications. As a result, PCB laminate manufacturers are constantly innovating to develop new, high-performance materials that address the limitations of traditional options.

Enhanced Performance and Safety

The latest advancements in laminate technology have led to the creation of materials with superior thermal conductivity for better heat management in electronic components. These advanced laminates not only address flame retardancy issues commonly associated with epoxy-based FR4 materials but also offer enhanced thermal performance, ensuring safety and reliability in high-power applications.

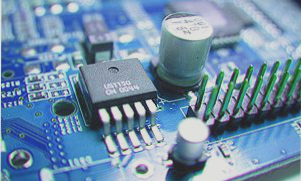

Understanding the Role of PCB Laminates

PCB laminates form the core structure of a printed circuit board, providing essential mechanical strength, electrical insulation, and thermal conductivity. Choosing the right laminate material is crucial in the PCB design process, as different projects require specific properties such as flexibility, high-frequency performance, or resistance to extreme temperatures.

Key Considerations in Laminate Selection

When selecting a laminate material, engineers consider factors such as electrical properties (dielectric constant, loss tangent), mechanical properties (strength, flexibility), and thermal properties (heat resistance). While epoxy resins like FR4 are commonly used, advanced materials like polyimide, PTFE (Teflon), and ceramic-based laminates offer specialized properties for diverse applications.

Recent Innovations in Laminate Technology

Recent developments have introduced laminates with higher thermal conductivity and enhanced flame retardancy, addressing the challenges posed by the increasing complexity and miniaturization of electronic devices. These advancements ensure improved electrical properties, reduced signal loss, and enhanced dielectric stability, crucial for high-speed and high-power applications.

Staying Informed for Success

As electronic components evolve to operate at higher speeds and power densities, staying informed about the latest laminate materials and technologies is essential. Understanding the properties and characteristics of different laminates enables engineers and designers to make informed decisions, ultimately contributing to the success of their projects.

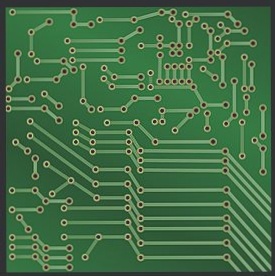

PCB Lamination: Enhancing Circuit Board Performance

PCB lamination is a critical process in circuit board manufacturing, where multiple material layers are bonded together to create a unified product. By combining non-conductive substrates with conductive tracks and pads, smooth electrical connections and mechanical support for the circuit board are ensured.

Core Materials in PCB Lamination

- Copper-clad laminate

- Pre-preg (B-stage resin-impregnated cloth)

- Copper foil

- Laminate sheets

These materials undergo curing to form a solid laminate, with properties influenced by factors such as fiber material, resin composition, and more.

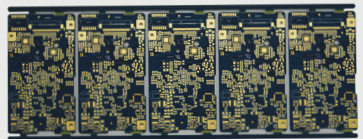

Types of Laminates and Their Applications

FR-4, a common laminate, is widely used in general PCB applications. Alternatives like halogen-free laminates and polyimide laminates offer improved electrical performance and environmental benefits. Ceramic laminates excel in high-temperature and extreme conditions, vital for certain specialized applications.

Advances in PCB Laminates for High-Frequency Applications

The demand for high-frequency applications drives the development of thin PCB laminates, crucial for high-speed data transmission. These laminates must meet stringent requirements for mechanical, thermal, and electrical properties, as well as chemical and moisture resistance.

Key Considerations for PCB Laminate Selection

- Impedance Control

- Thermal Management

- Moisture Absorption

- Chemical and Flame Resistance

- Corrosion Resistance

When choosing a laminate material, factors like signal transmission, heat dissipation, and resistance to environmental factors must be carefully considered.

Conclusion

The Significance of Laminates in PCB Manufacturing

Laminates play a crucial role in PCB manufacturing, offering benefits such as improved impedance control, enhanced thermal management, consistent performance, and reduced moisture absorption in dynamic environments.

With the continuous evolution of electronic technologies, the use of high-frequency laminates has become increasingly important in advancing PCB technology, particularly in industries like telecommunications, aerospace, and automotive.

Manufacturers who stay updated on the latest properties of laminates can make well-informed decisions to boost the performance and reliability of PCBs in today’s intricate electronic design and manufacturing landscape.