Exploring the Impact of Through-Hole Connections on PCB Thermal Resistance

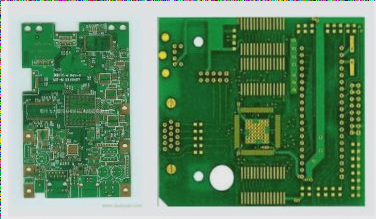

When considering the addition of through-hole connections on a PCB, it’s essential to understand how this affects thermal resistance. Typically, a through-hole connection involves drilling a hole about 12 mils (0.012 inches) in diameter, which is then plated with copper. The process adds approximately 1 mil (0.001 inches) of copper thickness to the inner walls of the hole. Additionally, the PCB undergoes ENIG plating, depositing nickel and gold on the outer surface of the copper.

Calculating Thermal Resistance of a Through-Hole

To calculate the thermal resistance of a through-hole, we use Formula 2, which considers variables such as the length of the cylindrical tube, thermal conductivity, outer radius, and inner radius. For a 12 mil hole, with an inner radius of 0.006 inches and an outer radius of 0.007 inches (copper plating), the thermal resistance is determined.

Importance of Through-Hole Connections

Through-holes play a crucial role in allowing higher power density on a smaller PCB area. By strategically placing vias, PCB designers can optimize thermal performance and reduce overall resistance. For example, adding multiple vias in a compact area can significantly decrease thermal resistance between layers.

Enhancing Thermal Performance

By strategically placing vias, such as in a 0.25 inch x 0.25 inch area, the thermal resistance of the PCB layers can be effectively reduced. For instance, adding 16 vias in this area can lower the overall thermal resistance, improving heat dissipation between the top and bottom layers.

Optimizing Heat Flow

It’s important to note that as heat flows through vias and reaches different layers, it will diffuse horizontally to adjacent material layers. Adding more vias can help in optimizing heat flow and reducing thermal resistance across the PCB.

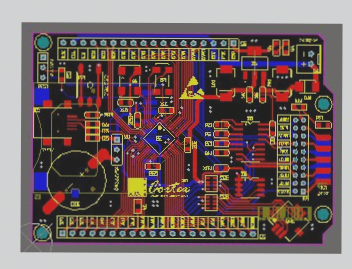

ISL8240MEVAL4Z Evaluation Board Specifications

- Board Size: 3 inches x 4 inches

- Copper Layers: Top and bottom layers are 2 ounces, inner layers are also 2 ounces each

- Through Holes: 917 holes with a 12 mil diameter

- Heat Dissipation: Vias spread heat across copper layers for higher power density

For any inquiries regarding PCBs, feel free to reach out to us at info@wellcircuits.com.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย