There is a commonly used process for surface treatment in circuit boards known as the immersion gold process. During production, the costs associated with immersion gold boards tend to be relatively high, leading to limited general usage. So, how can we determine which PCB boards require immersion gold? What types of circuit boards do not necessitate this treatment? We can analyze and evaluate based on the following criteria.

**Analysis of the Primary Applications for Immersion Gold Circuit Boards**

1. The board features gold fingers that require gold plating. The areas outside the gold fingers can be treated with either tin spraying or immersion gold, depending on the situation. This results in the typical processes of “immersion gold + gold-plated fingers” or “tin spray + gold-plated fingers.” Occasionally, some designers opt for a full-page immersion gold method to save costs or when time is critical. However, immersion gold does not achieve the thickness of gold plating, and if the gold fingers are subjected to frequent insertion and removal, the connections may become unreliable.

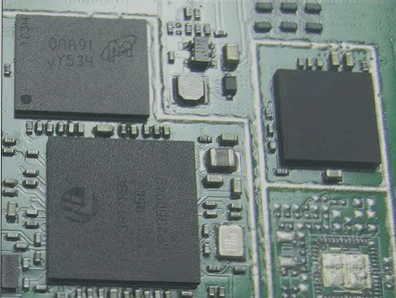

2. When the board’s line width and pad spacing are insufficient, it can be challenging to use the tin spraying process effectively. Therefore, for optimal board performance, processes like immersion gold are typically employed, as issues in production are rare.

3. Immersion gold or gold plating? The presence of a gold layer on the pad surface enhances solderability and stabilizes board performance. However, a disadvantage is that immersion gold is more costly than standard tin spraying, particularly when the gold thickness exceeds typical PCB factory standards. While gold plating is pricier, it generally provides excellent results.

By understanding these three scenarios, you will be equipped to identify when immersion gold circuit boards are necessary.

The immersion gold process involves depositing a nickel-gold plating layer that exhibits stable color, good brightness, smooth application, and excellent solderability on the surface of the printed circuit. What distinguishes the immersion gold process from other treatments?

**Differences Between PCB Immersion Gold Process and Other Processes**

1. **Heat Dissipation Comparison**

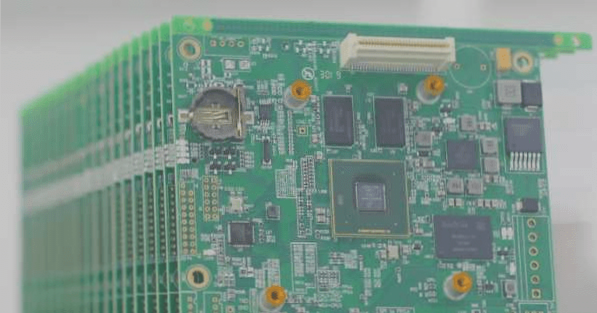

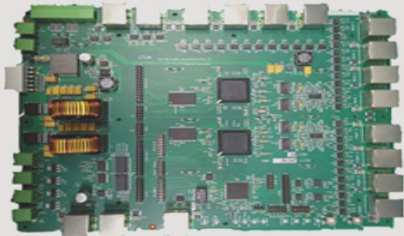

Gold offers excellent thermal conductivity, making pads composed of gold the most efficient for heat dissipation. Lower PCB temperatures contribute to enhanced chip stability. Immersion gold boards facilitate effective heat dissipation, allowing for comprehensive thermal management in areas like the CPU and BGA component soldering base, whereas OSP and silver boards provide average heat dissipation performance.

2. **Comparison of PCB Soldering Strength**

1. After three cycles of high temperature, the solder joints on the immersion gold board are complete, while the solder joints on the bright OSP board appear gray and dark, resembling oxidation. Following three high-temperature soldering processes, it is evident that the solder joints on the immersion gold board are intact, and the activity of the solder paste and flux remains unaffected. In contrast, the solder joints on the OSP process board are dull and lack luster, which compromises the activity of the solder paste and flux, making it prone to cold solder joints and necessitating increased rework.

2. Comparison of Electrical Measurability

Immersion gold boards allow for direct measurement both before and after production and shipment. The operational technology is straightforward and remains unaffected by external factors. Conversely, OSP boards feature an organic solderable film on their surface, which is non-conductive, preventing direct measurement. Therefore, measurements must be conducted prior to OSP application; however, excessive micro-etching post-OSP can lead to poor soldering outcomes. The surface of silver boards has moderate film stability but demands stringent external conditions.

3. Process Difficulty and Cost Comparison

Immersion gold boards are challenging to process, requiring advanced equipment and strict environmental protection standards. Due to the substantial use of gold, they incur the highest costs among lead-free boards. The process for silver fusion boards is somewhat less complex, with equivalent water quality and environmental requirements, resulting in slightly lower costs than immersion gold boards. The OSP board, on the other hand, has the simplest process and the lowest associated costs.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me