1. Natural Air Cooling and Forced Air Cooling

In PCB design for switching power supplies, two common cooling methods are natural air cooling and forced air cooling. For natural air cooling, heat sinks should be installed with their fins oriented vertically. If feasible, add several ventilation holes around the heat sink’s mounting area on the PCB to enhance air convection. Forced air cooling employs a fan to drive air convection, so the design of the air duct should align the heat sink’s fins with the fan’s exhaust direction. Near the exhaust fan, the thermal resistance of the heat sink is detailed in the table.

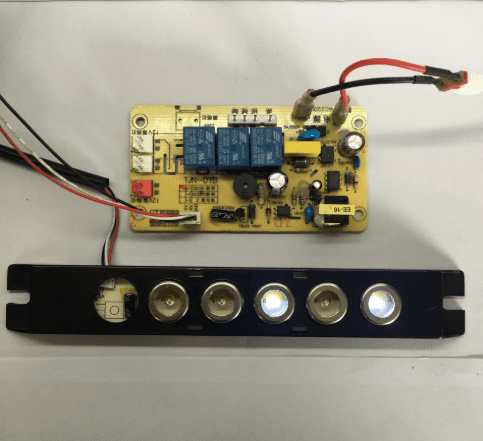

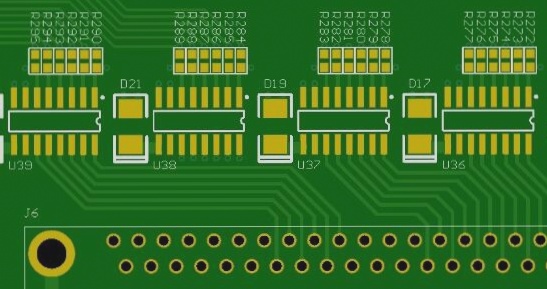

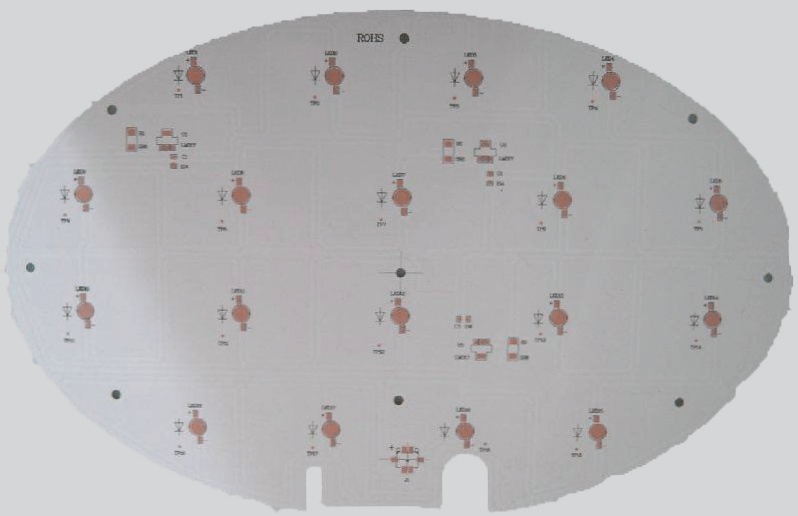

2. Metal PCB Board With the miniaturization of switching power supplies, surface-mount components are now widely used in crystal production, making it challenging to install heat sinks on power devices. The primary solution to this issue is employing metal PCB boards as the support for power devices. These boards include aluminum-based, iron-based, and copper-clad types. Their heat dissipation performance significantly surpasses that of traditional PCBs, allowing for SIVD element mounting. Additionally, copper core PCBs feature a copper plate insulation layer within the substrate, using high thermal conductivity epoxy glass fiber cloth adhesive or epoxy resin. They enable SMD components to be mounted on both sides, with high-power SMD components having their heat sinks directly welded to the metal PCB, utilizing the metal plate for heat dissipation.

3. Arrangement of Heating Elements The primary heating elements in switching power supplies include high-power semiconductor devices, their radiators, power conversion transformers, and high-power resistors. For optimal layout, arrange these elements from smallest to largest based on heat generation. Devices with lower calorific values should be positioned higher up in the air duct’s wind direction, while those with higher heat generation should be closer to the exhaust fan. To enhance production efficiency, multiple power devices are often fixed on a single large heat sink, which should be placed as close to the PCB edge as possible, maintaining a distance of at least 1 cm from the enclosure or other components. If several large heat sinks are present on one board, they should be aligned parallel to each other and the air duct’s wind direction. In vertical arrangements, place less heat-generating devices in lower layers and those with higher heat output higher up. Ensure that heat-generating components are positioned as far as possible from temperature-sensitive components, like electrolytic capacitors, in the PCB layout.

In PCB design for switching power supplies, two common cooling methods are natural air cooling and forced air cooling. For natural air cooling, heat sinks should be installed with their fins oriented vertically. If feasible, add several ventilation holes around the heat sink’s mounting area on the PCB to enhance air convection. Forced air cooling employs a fan to drive air convection, so the design of the air duct should align the heat sink’s fins with the fan’s exhaust direction. Near the exhaust fan, the thermal resistance of the heat sink is detailed in the table.

2. Metal PCB Board With the miniaturization of switching power supplies, surface-mount components are now widely used in crystal production, making it challenging to install heat sinks on power devices. The primary solution to this issue is employing metal PCB boards as the support for power devices. These boards include aluminum-based, iron-based, and copper-clad types. Their heat dissipation performance significantly surpasses that of traditional PCBs, allowing for SIVD element mounting. Additionally, copper core PCBs feature a copper plate insulation layer within the substrate, using high thermal conductivity epoxy glass fiber cloth adhesive or epoxy resin. They enable SMD components to be mounted on both sides, with high-power SMD components having their heat sinks directly welded to the metal PCB, utilizing the metal plate for heat dissipation.

3. Arrangement of Heating Elements The primary heating elements in switching power supplies include high-power semiconductor devices, their radiators, power conversion transformers, and high-power resistors. For optimal layout, arrange these elements from smallest to largest based on heat generation. Devices with lower calorific values should be positioned higher up in the air duct’s wind direction, while those with higher heat generation should be closer to the exhaust fan. To enhance production efficiency, multiple power devices are often fixed on a single large heat sink, which should be placed as close to the PCB edge as possible, maintaining a distance of at least 1 cm from the enclosure or other components. If several large heat sinks are present on one board, they should be aligned parallel to each other and the air duct’s wind direction. In vertical arrangements, place less heat-generating devices in lower layers and those with higher heat output higher up. Ensure that heat-generating components are positioned as far as possible from temperature-sensitive components, like electrolytic capacitors, in the PCB layout.