Independent PCB Testing by Huizhou Lier Laboratory

In mid-May, Wellcircuits engaged Huizhou Lier Laboratory for independent testing of PCBs manufactured in our facility. Huizhou Lier Laboratory, a trusted third-party testing institution and a subsidiary of Huizhou Lier Industrial Co., Ltd., is known for delivering reliable and unbiased test results for various domestic manufacturing brands.

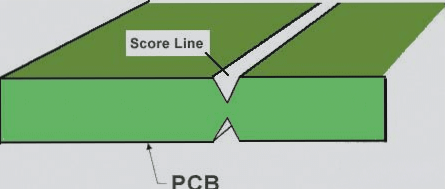

The testing took place at the PCB Reliability Testing Center of Huizhou Lier Laboratory over a two-day period. It focused on thermal stress detection, following the GB/T 4677-2002 test method for printed circuit boards. The test involved:

- 2-hour baking of the board at 130°C.

- 5 cycles of 10-second tin-bleaching at 288 ± 3°C.

Post thermal stress test, both visual and sectional inspections were conducted.

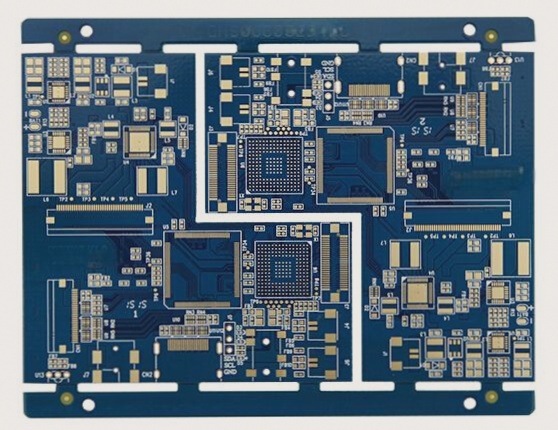

Following the thermal stress assessment, the sample underwent visual inspection, showing no significant blistering, delamination, or visible damage. Sectional examination revealed no abnormalities at the PCB hole locations, with intact copper and no wall separation.

Huizhou Lier Laboratory provided a detailed test report for the PCB samples. The report confirmed that post thermal stress testing at 288 ± 3°C, no significant anomalies were detected after 10-second tin drift.

In summary:

- Wellcircuits’ PCB raw material’s bottom copper is a standard 0.5OZ (17um) thickness, with over 16um of copper remaining after drilling, meeting Class A standards with minimal tolerance.

- Surface electrical copper thickness ranges from 24.49um to 25.76um, exceeding the industry standard of 35um (1OZ), showcasing superior quality.

- PCB copper thickness ranges from 25.27um to 28.78um, surpassing the international standard of 18-22um specified in IPC-6012, with uniform adhesion.

If you have any inquiries regarding PCBs or PCBA, feel free to reach out to us at info@wellcircuits.com.