Thermocouple Connectors: Essential Components for Temperature Measurement

Thermocouple connectors are vital for linking thermocouple wires, providing a convenient way to connect and disconnect them quickly. It is crucial that the pins and sockets of these connectors are made from the same material as the thermocouple wires to prevent measurement errors. Adhering to the ANSI color coding standard allows for easy identification of thermocouple calibration in connector design.

Types of Thermocouples

- Standard Thermocouples: These thermocouples comply with national standards, specifying thermal potential relationships, allowable errors, and standardized graduation tables.

- Non-Standard Thermocouples: Used in specific situations, these thermocouples lack the range and standardization of standard types.

Classification by Fixed Device Types

- Non-Fixed Device Type

- Threaded Type

- Fixed Flange Type

- Movable Flange Type

- Movable Flange Square Type

- Conical Protective Tube Type

Performance and Structure Types

- Detachable Thermocouples

- Flameproof Thermocouples

- Armored Thermocouples

- Spring-Fixed Thermocouples

Thermocouples utilize the thermoelectric effect for temperature measurement, generating an electromotive force when two different conductors are joined. This effect is used in various applications, from measuring gases and liquids in furnaces to monitoring solid surface temperatures.

The thermoelectric potential of thermocouples is determined by the conductor materials and the temperature difference between the junction points, ensuring accurate temperature readings without being influenced by the thermocouple’s shape or size.

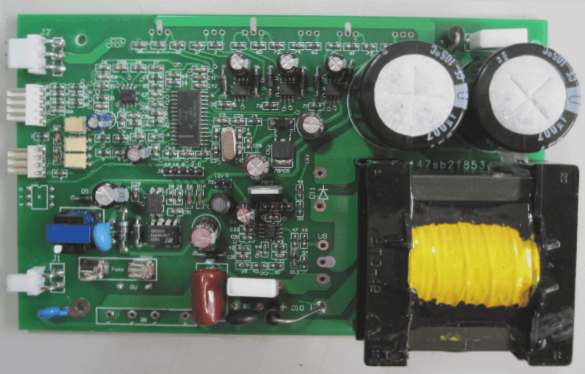

The Significance of PCB Connectors in Thermocouple Applications

The PCB connector plays a crucial role in linking the thermocouple with the temperature transmitter. Its primary function is to relay the temperature data from the thermocouple to the transmitter for further processing and conversion. Ensuring a secure and efficient connection is essential to maintain the accuracy and reliability of temperature signal transmission.

Proper installation and maintenance of thermocouple connectors are vital to prevent signal transmission errors that could compromise the stability and dependability of industrial processes.

- Reliable Signal Transmission: The PCB connector facilitates consistent and reliable transmission of temperature signals.

- Signal Accuracy: Ensuring a secure connection helps maintain the accuracy of temperature data transfer.

- Production Process Stability: Proper implementation of connectors is crucial for the stability and reliability of production processes.

For more information on PCB fabrication and its role in thermocouple applications, visit PCB Fabrication.